nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Jun 25, 2014 22:43:46 GMT -5

Hi Richard I found them in Kangerlussuaq an old american military air base in Greenland, now it's an civilian airport & a small settlement. I am on two week business trip there.   I drove to the scrapyard a few times & collected a VT50 & a T18 turbo & other good old school stuff. There must be about a hundred or more of used/empty JATO bottles at the scrapyard, and a lot of them is spread all over the old base & used as ashtrays. Cheers Erik |

|

|

|

Post by stoffe64 on Jun 25, 2014 23:40:09 GMT -5

Could you collect more of theese jatos?

I would be interested.

Cheers/stephan

|

|

nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Jun 25, 2014 23:46:15 GMT -5

Hi, could anybody help me with this unit? It's and old & long Janitrol aircraft heater ignition unit (p/n: 11C30), input 24 volts & 1.1 amps. It has a solid state vibrator (p/n: 12C60-A) at the end, labeled 24 volts & 60 CPS... Hertz??   It works, I know that because when I tested it with 12 volts I got zapped! Ouch!  Does anyone know what the output voltage & Joules is? Suitable for igniting diesel mist/spray? I want to replace my current ignition unit, which runs of 230 volts AC an run all the accessory part (starter, fuel & oil pump, ignition) of batteries 12/24 volt. Cheers Erik |

|

nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Jun 25, 2014 23:52:16 GMT -5

Could you collect more of theese jatos? I would be interested. Cheers/stephan Hi Stephan Sure I can  But I am leaving Kangerlussuaq tomorrow... I could collect and ship some for a reasonable charge, when I return to Kangerlussuaq in 2-3 months.  Cheers Erik |

|

|

|

Post by enginewhisperer on Jun 27, 2014 2:05:04 GMT -5

CPS will be Cycles Per Second - so yep, Hertz  |

|

nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Jul 1, 2014 21:01:37 GMT -5

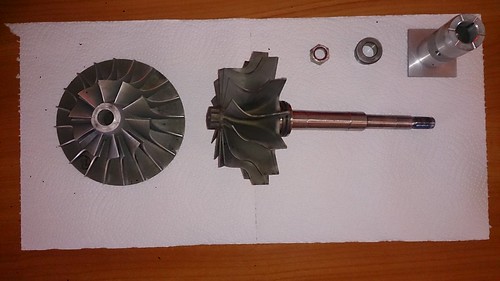

Hi I partly disassembled the T1810 turbocharger for inspection & measurements. Here is the data from my measurements, T1810. Compressor wheel diameter; Inducer 74.5 mm, exducer 127 mm Turbine wheel diameter; Exducer 85.6 mm, inducer 111 mm Compressor wheel hub diameter; 21.6 mm JetSpec's mass flow rate; 1.47 lbs/sec. (10 % more than VT-50).     The turbo looks good just some old oil which I will remove later on. The shaft turns freely and with minimum play. I also ultrasonic cleaned a spare set of "rotating assembly " from a VT-50, which turned out pretty nice & clean.   Before & after cleaning.   Here is the data from my measurements, VT-50. Compressor wheel diameter; Inducer 73.5 mm, exducer 129 mm Turbine wheel diameter; Exducer 88.5 mm, inducer 118 mm Compressor wheel hub diameter; 28.6 mm JetSpec mass flow rate; 1.33 lbs/sec. Another thing...  Is it possible to visually see the difference between a GMR-235 alloy turbine wheel & one in Inconel???  I noticed the turbine wheel on the T1810 was more smooth & shiny than the VT-50 turbine wheel which had a more "rough/grainy" surface & darker... Or could it just be the casting method...? Cheers Erik |

|

|

|

Post by racket on Jul 1, 2014 23:09:52 GMT -5

Hi Erik

Its not possible to determine the turb wheel material by just looking at it :-( ..............all you can do is run the engine at "reduced" temperatures that are safe for GMR 235.

Nice set of vane in the comp diffuser

Cheers

John

|

|

nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Jul 3, 2014 19:11:45 GMT -5

Hi John Okey I was hoping that there would be a visual difference, but that's fine I will set the max TOT at 650° C  I found a used hydraulic gear pump, a Lamborghini!  Make: Lamborghini FUNO, model: HLPSG/131DF. Split it apart & ultrasonic cleaned all the bits & reassembled it.    I couldn't really find data on the unit by googling it, does anyone know about this pump? I would like to replace my current Shurflo diaphragm oil pump with this gear pump if it is suitable. Cheers Erik |

|

|

|

Post by racket on Jul 3, 2014 20:48:42 GMT -5

|

|

nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Sept 1, 2014 12:06:40 GMT -5

Hi John I have a Shurflo oil pump which is producing good pressure & flow for my current setup. But I am not sure if it can handle the VT-50 or the T18, the Subaru pump could be a good candidate if the Shurflo is inadequate. I have a spare turbo laying around, a Holset H2D with Inconel turbine. When I had the turbo disassembled for cleaning I noticed that two of turbine inducer blade tips where shorter?! Actually about 2 mm shorter than the rest.  Here is a picture of another turbine wheel (for illustration) I painted the missing/trimmed? parts. The edges of the tips have clean cuts?. Could it be a damaged wheel or balancing cuts/trims??? 2-3 mm seems a bit too drastic for balancing but the tips is very nice and "clean". No signs of damage on the rest of the turbine wheel or the turbine scroll. Cheers Erik |

|

|

|

Post by racket on Sept 1, 2014 17:16:53 GMT -5

Hi Erik

Yep , balance reduction , I've seen it on other wheels , turbo balancing can be a bit crude at times, it saves taking off a lot more metal at a smaller radius :-)

Cheers

John

|

|

ashpowers

Veteran Member

Joined: February 2011

Posts: 207

|

Post by ashpowers on Sept 2, 2014 1:42:12 GMT -5

"Crude" is crudely understated in this case..... There are so many other points that can be shaved to achieve balance that wont affect efficiency....

|

|

nersut

Veteran Member

Joined: September 2012

Posts: 223

|

Post by nersut on Sept 2, 2014 12:04:25 GMT -5

Hi Erik Yep , balance reduction , I've seen it on other wheels , turbo balancing can be a bit crude at times, it saves taking off a lot more metal at a smaller radius :-) Cheers John Hi John Thank you for the explanation.  I can't really make my mind, I have two options: 1. Continue on my current setup but replacing the turbocharger with the Holset H2D ( with Inconel 713C turbine instead of my current GMR 235) and use a VT-50 turbine wheel as power turbine. 2. Go bigger by building a new GT based on the Garrett T18 with reverse flow combustor (similar to the picture below) and use a Allison 250 3rd stage turbine wheel as power turbine.  Cheers Erik |

|

|

|

Post by racket on Sept 2, 2014 17:01:03 GMT -5

Hi Eric

Go BIGGER :-)

Cheers

John

|

|

|

|

Post by finiteparts on Sept 2, 2014 20:26:22 GMT -5

Hi Erik,

I wonder if you have cleaned off the nice oil flow traces in the diffuser section of that T1810 that you have pictures of on your July 1 post? If not, would it be possible to get a few close up shots of the oil traces on a diffuser passage from both the sides of the case? I have a VT50 that I think has some nice oil traces on it that I need to go out an take some pictures of. Those traces are great for "seeing" how the flow scrubs the wall or doesn't. I can't zoom in on the pictures you posted, so I can't tell if that is maybe a wake region formed due to high flow rates or maybe it's a tripped flow due to the entrance area of the diffuser (since there seems to be some clean spots in the center of several diffuser passages entrances). Either way it is really neat to look at!

Thanks!

Chris

|

|