sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 12, 2012 13:14:57 GMT -5

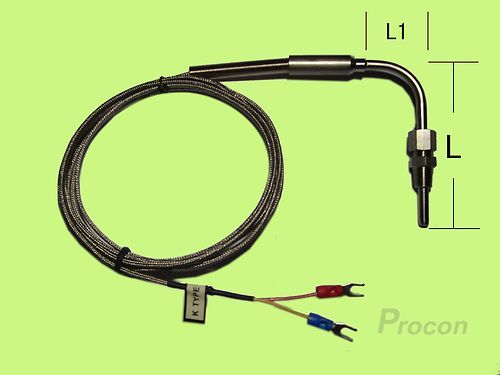

Hi, Today I ordered few pieces for my turbine switches 5pcs led illumination  Silver solder, high content silver  Laser RPM meter  300w 24v motor for oilpump  Gauges    9-28V 30A DC Motor Speed Control PWM  0.7mm ss tubes  K type probe up to 1200 c and display   Servo tester  Oilfilter couplings  For oilcooler gonna use old AT cooler, also I managed to get couple new fuelpumps for free, that made my day. Sven |

|

|

|

Post by ernie wrenn on Nov 12, 2012 17:38:52 GMT -5

Damn... lets just order all the nice parts!!!!

ernie

|

|

wolfdragon

Senior Member

Joined: April 2011

Posts: 287

|

Post by wolfdragon on Nov 12, 2012 19:45:07 GMT -5

it's no fun to just buy everything that you know will play nice with each other...

the real fun doesn't start until after the busted knuckles and the associated swearing fit happen

|

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 13, 2012 11:30:47 GMT -5

Hi

I dont have milling machine, its cheaper to buy some parts like this olifilter housing. I dont know, but only thing here on the list, what I may build by myself is pwm controller. I have drawings made for controller, but this box was only 15 eur( same price for only components to buy separately)

I already have fun building this project and thanks for jato forum I have managed to get this far.

Today I refurbished my used powersteering pump, now I have to figure out the best way,how to connet it to the dc motor.

Cheers

Sven

|

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 18, 2012 11:06:10 GMT -5

Little build progress I cut vanes into right height and shape, also made vane top ring. Couple pics    Also bought stainless steel tubes for making oil and fuel tank.  Cheers Sven |

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 18, 2012 15:19:24 GMT -5

Quik question, Im was thinking about oil lines and Id like to go with AN type fittings and stainless braided hoses, I was thinking about use AN8 size for pressure side, and AN12 for free flow. What you guys reacon?

Sven

|

|

|

|

Post by racket on Nov 19, 2012 3:29:02 GMT -5

Hi Sven

The bore of the drain tubing needs to be the diameter of the drain hole in the turbo's centre housing , most a pretty big .

As for the supply line sizing , as long as the pressure gauge reading taken from a pickup at the turbo's oil inlet port is indicating the desire pressure then its big enough .

Cheers

John

Cheers

John

|

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 19, 2012 11:26:36 GMT -5

Then Im on the right way, thanks again John

|

|

wolfdragon

Senior Member

Joined: April 2011

Posts: 287

|

Post by wolfdragon on Nov 19, 2012 19:04:14 GMT -5

Need to be careful about the braided hoses, most likely they will not handle the temperatures (the rubber liner not the braid) of the exhausting oil and/or the core case temperature.

Hardlines seem to be the easiest way to go, and with AN fittings, your flare angle will be known and easy to get a flare tool for.

|

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 20, 2012 13:02:01 GMT -5

Hi and thanks for reply Good point, I was thinking about use ptfe and stainless braided hoses(not regular rubber), and turbine side gonna get heatshielded, oil exhausting gonna be stainless tubing. Manufacturer promises 180 celsius for ptfe hose, before going bad, with oilcooler I hope to keep temperature lower than that  Lets see I have so much do to before that, weekends(sometimes even not then) I have only free time to build my projeckt, wish I have more time  Sorry for my spelling, its terrible :S Cheers Sven |

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 24, 2012 10:03:21 GMT -5

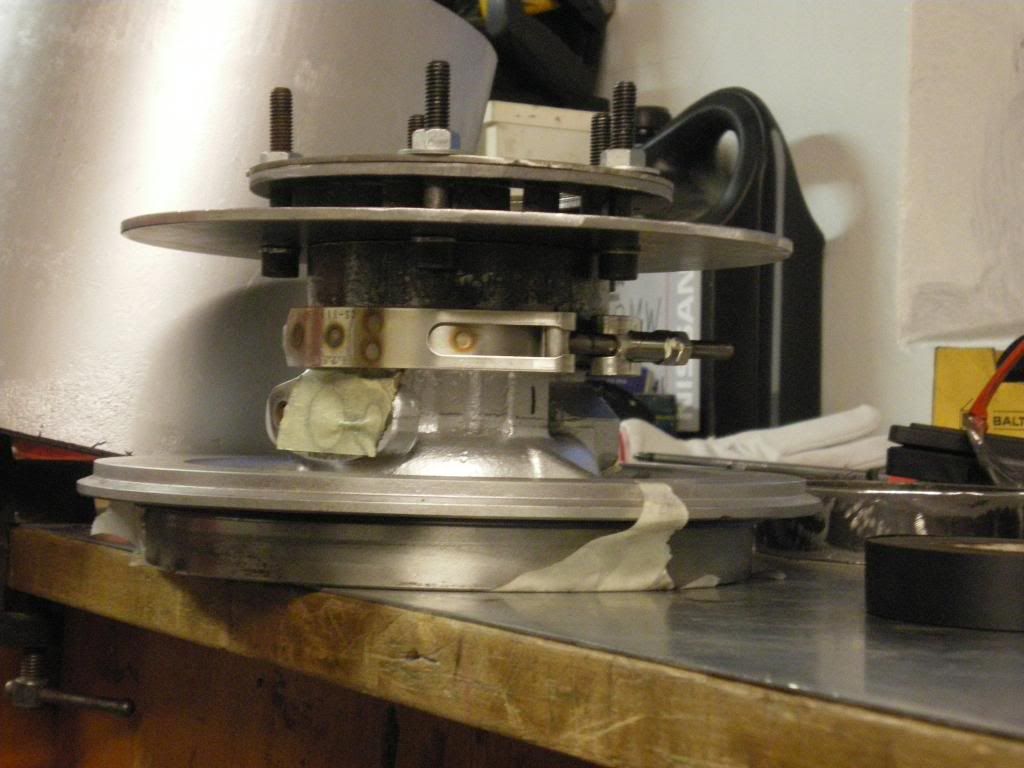

I had free time at this morning, so went to the garage. Welded clamp holder/turbine leg together.  drilled holes to attach vanes and upper plate together.     My dc motor arrived, so I tried the way how to connect it to my Oil pump.   Cheers Sven |

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 25, 2012 9:55:56 GMT -5

|

|

|

|

Post by Johansson on Nov 25, 2012 15:19:22 GMT -5

Good progress Sven, looking forward to see more of this build!  |

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 25, 2012 16:15:22 GMT -5

Thanks Anders, Building this engine is good fun, hope to get new updates soon!

Sven

|

|

sven

Veteran Member

Joined: February 2012

Posts: 102

|

Post by sven on Nov 26, 2012 15:17:34 GMT -5

Today my old friends visited me, I showed them my old project(valveless pulsejet engine) they never seen anything like this before  First startup video for you guys, just for entertainment:) At this time gas valve was too sensitive, fixed for now. Sven |

|