gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on Nov 11, 2015 22:45:38 GMT -5

I thought I would start a new thread for the jet dragster I recently bought. I will load more pics and details once I get them together, but we started it yesterday to check for leaks, gauges working etc. The wiring like most race cars has been chopped and changed over the years and at the moment we don't have EGT or engine oil pressure working so will look into that. On the first run we had a wet start and a few flames, my 2 mates had not been around a jet starting before and caused a bit of sphincter clenching but all ok.    Unfortunately I don't have a video of that, but just for your amusement I have a video of the second run, sorry that quality is terrible but I had to run the car in the shed and the camera facing into the light. www.youtube.com/watch?v=TvSc7po8Z8k&feature=youtu.beCheers Ian... |

|

|

|

Post by turbochris on Nov 12, 2015 14:40:49 GMT -5

J34 is a tough engine

|

|

|

|

Post by smithy1 on Dec 3, 2015 18:12:56 GMT -5

Hi Ian,

Any "developments" on the J34 powered machine..?

Regarding oil pressure...you should be seeing ~40-45psi, our old J34-34 track dryer runs ~42psi at an idle of ~43%, the EGT is usually ~540C-ish at this point, during start and ramp up to idle they can often reach 800C+, just make sure you keep an eye on the egt and regulate via the throttle and keep the starter into it until you reach at least 30%. The engine you have should show similar numbers. The "Stellite" blades in the old J34's can handle 1000c for a very short period, but I wouldn't keep it there for more than a few seconds. Shut down if you're not happy...there's always time for another start....but not if the turbine is dribbling out the back!! ;-)

I've actually started that car quite a few times over the years when Colin Dicker owned it and I don't remember it being a pig to start. I would open the throttle to the idle detent when the rpm goes through 7-8% and she should light of pretty much straight away, as mentioned, just keep the egt in check with the throttle and you should be good to go. A few little flames out the back is nothing to worry about as long as the EGT's aren't silly.

Cheers,

Smithy.

|

|

gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on Dec 4, 2015 9:27:13 GMT -5

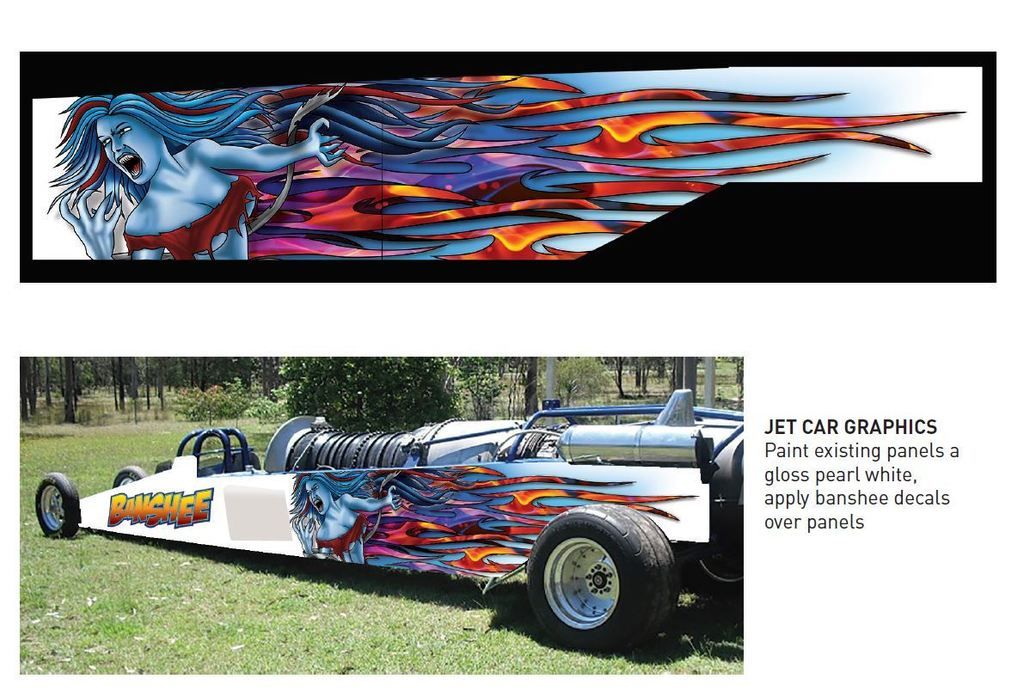

Hi Smithy, Thanks for that, I did not know that the car was owned by some one else between Rosco McGlashan and Graham Slapp, did Colin Dicker run it much? I think I have the oil issue worked out. I removed the oil pressure sender and spun I over…. nothing  . Plenty of oil in the tank but I think because it is mounted low in the frame and had not been run in a while it had all drained back. So I cracked a few lines and bled it up to the pump and now spinning it over gets oil to the sender. I have not started it yet but I think that was the problem. The EGT is still an issue. I know that I should not do it this way, but I set my multi meter to continuity and touched the back of the gauge and got a flicker so I think that is ok, but checking the voltage from all the thermo-couples gives wildly different reading for each of them. Not sure why? The wiring has lots of splices and taped connections so a friend of mine who does wiring on old British bikes is making a whole new harness mainly to tidy things up a little. Only problem is he does sand drags and fell and broke his arm a month ago so no harness for a while  I have made a new start cart basically using Anders idea for his Viper starter with a few changes, will load that later. My brother has a business doing signs & wrapping and has been working on the panels. We have decided to call Banshee and the F2H Banshee the engine originally came from.  One of the guys he works with said the picture reminded him of his ex-girlfriend    no comment. The main problem I am having at the moment is a trailer that will work for both cars. When I bought the car Graham wanted to keep the trailer but I have been pestering him a little and he said he may sell it when he retires. The trailer works well for the jet car has a cut out in the tail to clear the belly so the Land speed turbine car would be a problem. I have been working on designing an 8 meter long trailer on airbags that will drop to give a 3-degree approach angle. So that is where I am at, been trying to get more done but there only seems to be 25 hours in the day and here in West Australia there does not seem to be many other people that are interested in drinking beer, eating pizza’s and working on turbine race cars so it is up to me…. But I guess thats all part of the fun… ' Cheers Ian... |

|

|

|

Post by smithy1 on Dec 9, 2015 4:13:55 GMT -5

Hi Ian....My bad, I had Colin Dicker's name in the back of my head, he had a similar car...Graham had the two J-34 powered cars for well over ten years I believe....I understand he still has the Voodoo Chilli car in Brisvegas. He also has a Naturally aspirated Nitro digger, I've yet to see it in person though...! I still have all my J-34 "Holley" FCU test gear at my work. Spoke to Graham the other night via BookFace..

With the EGT sensors, they should be wired in parallel.. so if one fails the rest will still work, run your multi-meter over them and check to see if you have continuity, correct resistance etc.... With the start cart, (I'm not sure if Graham supplied you with one), just be sure to have a 12v "soft start" running through a relay and solenoid, you only need to hit it for 2-3 seconds just to get the turbine spinning to lessen the load shock, then you can hit it with 36v. There's an accessory drive 90 degree "quill" (shaft, only ~1/2" dia) which runs off the compressor main shaft and drives the accessory gearbox, it can be over-stressed by the starter if hit to hard, some have been known to snap....hence the use of the soft start.

Graham used to transport the two dragsters around interstate using a 40ft container, they sat in it side-by-side at an angle...very neat too. I believe Steve Mirams came up with that idea...otherwise it would've been an "over-under" setup.

Cheers,

Smithy.

|

|

gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on Jan 31, 2016 1:16:57 GMT -5

Been doing a few bits and pieces on the jet car lately, the wiring was in need of a bit of tidy up so working on that now.  There are a few wires that seem to change colour from one end of the harness to the other so will pull the whole lot out and start again. Now a question for the smart people here.... With jet car came a container load of spare engines etc.  One engine was partly disassembled and the 2 turbine stages and the guide vanes are out..   My question is it feasible to use these as a power turbine behind jet if the after burner is removed?? I know it would need a gearbox to handle a lot of power and this is probably more of a rhetorical question BUT would the turbine convert the thrust to shaft horsepower? Cheers Ian... |

|

|

|

Post by racket on Jan 31, 2016 15:46:23 GMT -5

Hi Ian You'd only need one stage of freepower . A gas producer doesn't know or care if its a freepower wheel, jet nozzle or A/B downstream producing the backpressure on it ............BUT, each of those must be sized correctly to produce the desired backpressure . If the turbine wheel you propose to use is the same size as the gas producer's largest turb wheel , then it would be necessary to "dump" a portion of the gas producers outflow through a jet nozzle or small A/B , with the remainder going through the "undersized" freepower wheel Normally a freepower wheel would have roughly twice the flow area of the second stage turb wheel in your engine . When I built my two shaft kart jetandturbineowners.proboards.com/thread/40/2-shaft-turbine-kart-build its freepower wheel was "undersized" so I had to "dump" gases , it wasn't a problem , the dump jet nozzle flowed ~40% of the TV84 gas producers output, the interstage total pressure stayed the same as when the "pure jet" TV84 was equiped with a simple jet nozzle. You could end up with an engine that has shaft horsepower plus "reduced" afterburner noise, and better fuel economy and power :-) Cheers John |

|

|

|

Post by smithy1 on Jan 31, 2016 16:45:13 GMT -5

Hi Ian, Ah....the good old J-34 with "Stellite" turbine blades....nearly indestructible. Those 60 fuel nozzles will do your head in too..!  3000lbs+ of thrust converted into shaft-horsepower = HUGE..!  Smithy. |

|

|

|

Post by racket on Jan 31, 2016 22:08:33 GMT -5

Hi Ian

I've done a tad more research on this and found a reference in one of my books to there being an "experimental??" turboprop variant of the J34 . it was the Model 25D , at 3,700 HP .

Now the J34 only had a lowish PR of 4.35 :1 but a respectable thrust output of ~55-60 lbs/pound of airflow , this would have required a decent jet efflux of ~1800 ft/sec requiring a PR across the jet nozzle of ~1.8:1 , this is quite high compared to the PRs across each of the two turbine stages of only ~1.55 :1 on each stage .

Now normally a single turbine stage could have powered the compressor wheel , as was done with the early RR engines , having two stages probably "fitted" better with the axial comp stages rpm .

This could be an advantage for you as the higher PR previously available in the "jetpipe", and now as an interstage pressure , would mean potentially higher gas velocities available to get the gases through an otherwise "undersized" freepower wheel .

Yep , its doable :-)

Cheers

John

|

|

gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on Feb 1, 2016 7:00:24 GMT -5

Hmmm now you guys have got me thinking..... This was meant to be a rhetorical question The Nimbus engine is pretty well ready to go and I need to build a car... but 95% of the pre - build aero work is done. On the other hand the J34 with 4 times the power of the Nimbus sounds great but there is all the work designing & building the gear box etc. Plus although the car is done, it's probably not the most aerodynamic thing at the moment to be running at 300mph ++ on the salt, but may be interesting at the drags..... Based on the times the car has done in the past at the drags, top speed and it's weight (although it makes 3000lbs of thrust) it is only using about 1200 "effective" horsepower. A lot of people have converted engines from turbo shaft to jet, going the other way could be interesting. Maybe a spectacular burnout car....   Going to take more cogitating ......... Cheers Ian... |

|

|

|

Post by frankenhealey on Feb 1, 2016 13:03:06 GMT -5

Maybe a spectacular burnout car....   Can I be your tyre supplier? Please please please  |

|

|

|

Post by racket on Feb 1, 2016 22:08:20 GMT -5

Hi Ian

Yep , thrust is pretty pathetic compared to shaft horsepopwer.

It'd be an interesting "conversion " .

Cheers

John

|

|

gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on Feb 2, 2016 7:28:28 GMT -5

Just thinking out loud here, if I could get a beefy right angle gearbox that is attached to the turbine facing forwards & the output shaft pointing down into a diff laying on its back that should get the power out under the engine where it needs to be. Then if I mounted the turbine with a "generous" tip clearance say ~ 30mm ? that would give the blow by to keep the back pressure under control hey presto.... ? Something to think about.  Ian... |

|

|

|

Post by racket on Feb 2, 2016 14:51:15 GMT -5

Hi Ian

Maybe turn the diff 90 degrees so the input is vertical , feed the gases to a plenum "under" the freepower so the exhaust is vertical to provide some down force , any sort of bypass could be mounted off the plenum like a wastegate and directed backwards through a jet nozzle .

Cheers

John

|

|

gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on Feb 3, 2016 0:43:46 GMT -5

Hi Ian Maybe turn the diff 90 degrees so the input is vertical , feed the gases to a plenum "under" the freepower so the exhaust is vertical to provide some down force , any sort of bypass could be mounted off the plenum like a wastegate and directed backwards through a jet nozzle . Cheers John Yep, that's it!!! Only 1 set of gears to go through and all those can be well out of the hot gas flow and as you said have a rear facing "waste gate". Just thinking I even have the shaft all the bearings. In the earlier pictures of the turbines, the one still on the motor has a splined shaft about 100mm dia 900mm long that connects it to the compressor with all the bearings etc..... My son has abandoned a 1970's Holden statesman without an engine here so that may be being built into a burnout car...  I have a feeling I am going to have to look into this more, I'll post some pics and drawings once I have done some measurements. Cheers Ian... |

|