|

|

Post by Johansson on Oct 30, 2018 8:40:46 GMT -5

Anyone here who has had the opportunity to look inside one of the newer AMT jets? According to the website they have a "revolutionary design diffuser stage" so it would be interesting to know how it differs from the usual wedge design. AMT Nike |

|

|

|

Post by racket on Nov 4, 2018 16:26:58 GMT -5

Hi Anders

I think its more an "axial" diffuser rather than radial , a bit like the old large radial aero jet engines , that way the outer case is relatively small diameter for the sized hole in the front .

Cheers

John

|

|

|

|

Post by Johansson on Nov 5, 2018 12:27:26 GMT -5

The engines look really small in diameter compared to the inducer diameter, so that makes sense.

|

|

monty

Senior Member

Currently being spanked by mother nature.......

Currently being spanked by mother nature.......

Joined: September 2018

Posts: 400

|

Post by monty on Nov 5, 2018 20:23:33 GMT -5

Do you guys have any example engines to look at? I'm curious.

Monty

|

|

|

|

Post by Johansson on Nov 7, 2018 17:15:54 GMT -5

Nope, I had hoped someone here would have a pic or two of the internals.

|

|

monty

Senior Member

Currently being spanked by mother nature.......

Currently being spanked by mother nature.......

Joined: September 2018

Posts: 400

|

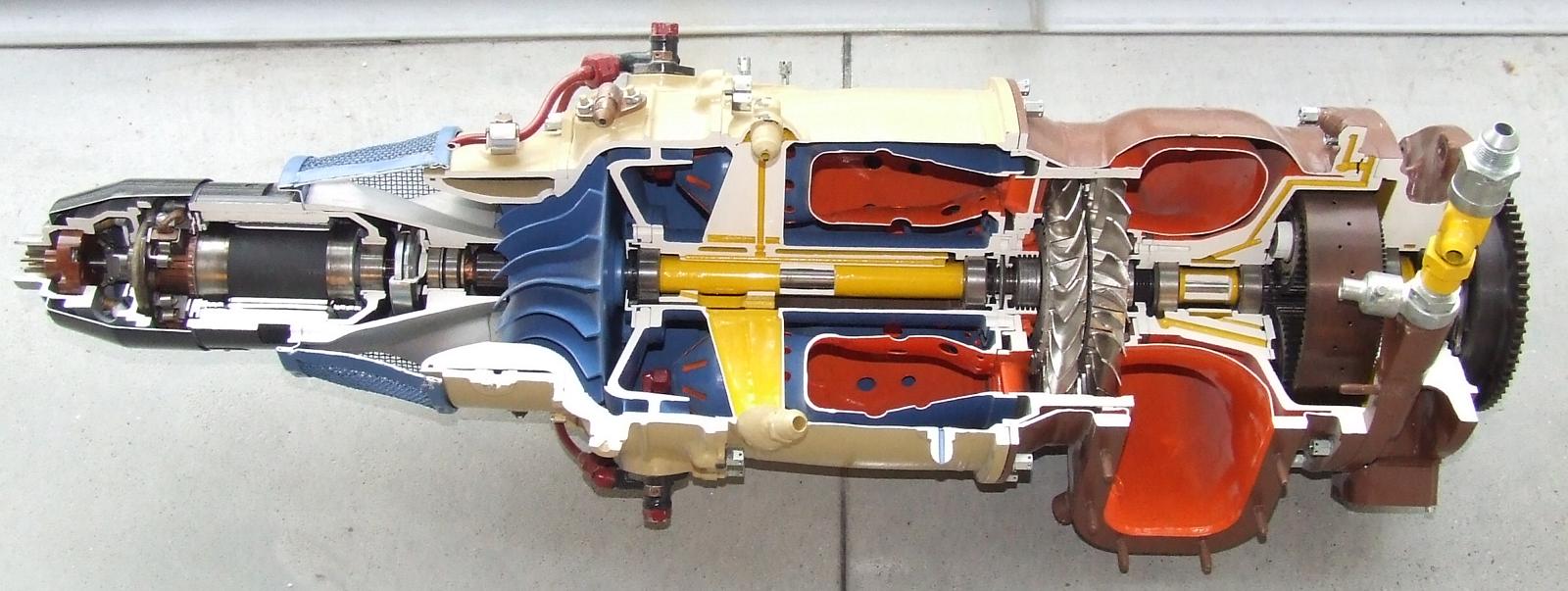

Post by monty on Nov 8, 2018 8:29:34 GMT -5

Maybe something like this?? Except straight to an axial low solidity vane type...

|

|

turbotom

Junior Member

Joined: June 2011

Posts: 59

|

Post by turbotom on Nov 8, 2018 18:53:53 GMT -5

Maybe something like this?? Except straight to an axial low solidity vane type... Wow, what type is that engine? If I should risk a guess, I'ld say it's of Russian origin. Just like this TS-20B jet fuel starter that actually contains a radial/diagonal compressor with only an axial set of diffuser vanes. Pretty inefficient, though...  |

|

CH3NO2

Senior Member

Joined: March 2017

Posts: 455

|

Post by CH3NO2 on Nov 9, 2018 14:18:25 GMT -5

Very interesting.   |

|

turbotom

Junior Member

Joined: June 2011

Posts: 59

|

Post by turbotom on Nov 9, 2018 16:30:02 GMT -5

The inner surface of the metal part of the compressor cover is serrated / roughened because in the real engine (not the sectioned model) this area is coated with an abrasible polymer (actually, if you look carefully, you will notice the recessed area where the casing covers the compressor on the TS-20B model as well, for the same purpose). This way, the compressor clearance can be kept smaller without risking welding or other substantial damage if the two components touch each other while the engine runs. The increased surface area (of the serration) helps keeping the coating where it's supposed to be during all the heat cycling and things. I've seen the result of such a coating coming loose at a BMW/MTU 6012 - not many parts of the engine salvagable after such an event. |

|

CH3NO2

Senior Member

Joined: March 2017

Posts: 455

|

Post by CH3NO2 on Nov 9, 2018 20:10:31 GMT -5

I must admit I thought of glass micro ballon filled epoxy as an abraidable seal but didn't consider serrations to enhance bonding strength. Now that you mention the destructive potential it doesnt seem like such a good idea.  Thanks for the heads up! |

|

monty

Senior Member

Currently being spanked by mother nature.......

Currently being spanked by mother nature.......

Joined: September 2018

Posts: 400

|

Post by monty on Nov 11, 2018 18:26:54 GMT -5

Wow, what type is that engine? If I should risk a guess, I'ld say it's of Russian origin. Just like this TS-20B jet fuel starter that actually contains a radial/diagonal compressor with only an axial set of diffuser vanes. Pretty inefficient, though... Thomas,

I have no idea! I just did an image search for "jet engine cutaway" That one was interesting.

That TS-20B starter is cool. I'd say that the thermodynamic efficiency is irrelevant. The power density is probably the main objective, and from the looks of it the power/diameter was the main concern. Makes sense if you are trying to cram the proverbial 10lbs in a 5lb bag...which aircraft designers always are. Neat design!

Monty

|

|