miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 22, 2014 8:58:04 GMT -5

Thanks John for the great tips! Turbine now runs perfect, no more flame outs or hard starts  TOT also did decrease.. I'll post more info later. |

|

|

|

Post by Johansson on Mar 22, 2014 13:29:19 GMT -5

Congratulations! Lets see some video!  |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 22, 2014 18:00:51 GMT -5

Here's a short clip: youtu.be/lbzgT4o5WrsLike said, we made it run clean with no problems. You might see the happiness in the video  Today temperatures were even lower than earlier, TOT was 350°C at idle (from 0 to 0.5bar) after that it started to climb but stopped at 650°C at 2.5bar. Tomorrow we'll add a pressure gauge to the jet pipe so we can make an inclusive log of running. After that, maybe adding the freepower turbine?! Can't wait! |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 23, 2014 14:13:01 GMT -5

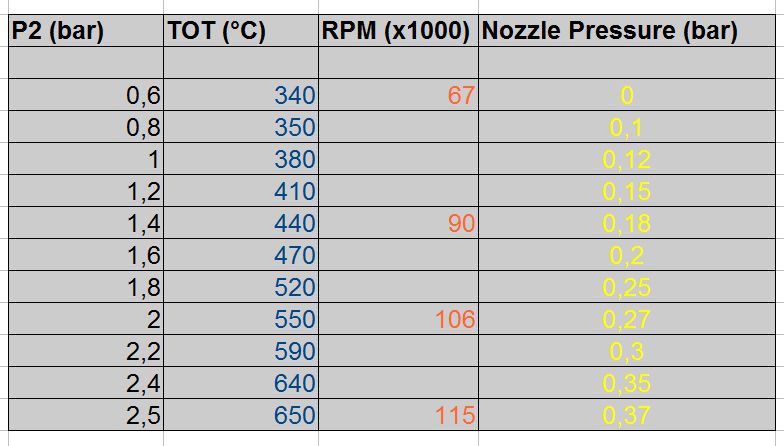

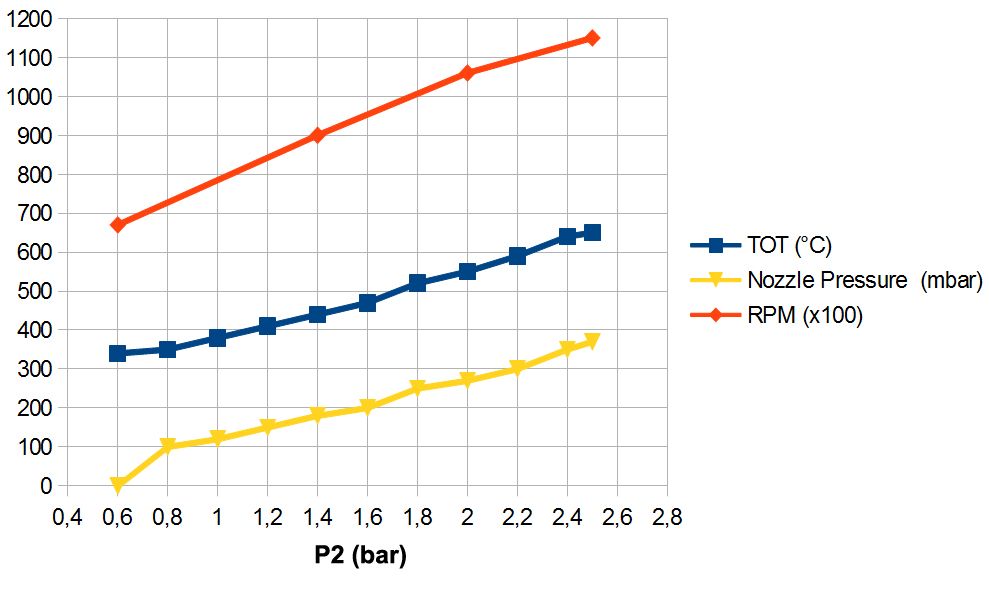

Don't get bored, I've got more info and video to offer  Here's some numbers, what do you think? It has a jetpipe with 51mm diameter out.   Video of making a log: youtu.be/Kzu5FZ8TT9oWalkaround, water spray, glowing metal.... youtu.be/3VVrrdszFyo |

|

|

|

Post by racket on Mar 23, 2014 20:07:39 GMT -5

Hi Miuge

Good numbers :-)

3.5 PR at 115,000 rpm - 1580'/sec is right on what it should be , certainly not in the high flow choke region , but could be between the "best" position and the surge line due to your turbine wheel size .

Your Jet Pipe pressure at 0.37 bar - ~5.5 psi is also pretty good , I'd expect it to be a little bit higher , where is your pitot tube entry positioned ??

But the numbers are well within the ball park , I'll do some more complete calculations to see if theres any other variables ..............they're good enough to start feeding into a freepower though :-)

Cheers

John

|

|

|

|

Post by racket on Mar 23, 2014 20:52:46 GMT -5

Hi Miuge

Some numbers :-)

A 3.5 PR at say 72% comp effic with 15 deg C ambiant will produce a temp rise in compression of ~172 C degrees for a T2 of ~187 deg C in your air delivery tube at 2.5 bar P2.

Assuming a pressure drop across your flametube of 5% ( average sorta number), your 3.5 PR becomes a 3.325 PR going into the turb stage .

The 172 C degree rise in compression will require a temp drop thru the turbine stage of ~147 C degrees , we'll add that onto your TOT for a T I T of ~800 deg C, this is a nice safe temperature, it could be increased if your turbine wheel is made of Inco 713C , the material used for good quality modern automotive turbos , but as your turbo is from a diesel it could have a wheel of GMR235 which can't take as high a temperature , so play it safe at this time .

Assuming a turbine stage efficiency of 70% this will need a PR of ~2.39 across the stage to produce the required 147 C degree drop , leaving a PR in the jetpipe of ~1.39 or 0.39 bar , pretty close to your figure :-)

A 1.39 PR across your jet nozzle from a temp of 650 C - 923 K will produce a temp drop of ~68 degrees C at 95% nozzle efficiency and a jet velocity of ~1,300 ft/sec .

Your 51mm dia jet nozzle will have an effective flow dia of say 49mm after allowing for the boundary layer , that 49mm - 1.93" dia - 2.922sq ins - 0.02 sq ft , will pass ~26.3 cubic ft/sec at 1,300 ft/sec , density at , 650 minus 68 or 582 C -855K is ~38.7 cu ft/lb , your flow out the jet nozzle of 26.3 cu ft/sec divided by our density of 38.7 cu ft/lb gives us a mass flow of 0.68 lbs/sec , producing a thrust of 27.4 lbs or ~12.5 kgs .

Our calculated mass flow of 0.68 lbs/sec or 40.8 lbs/min is roughly correct , your 55mm - 2.16" comp inducer has an area of 3.68 sq inches , now the average flow for turbos is ~11 lbs/sq in/minute so 11 X 3.68 = 40.5 is pretty close to our calculations above .

Looking good :-)

Cheers

John

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 24, 2014 5:56:22 GMT -5

Hi John! Nice calculations, I read it a few times to comprehend :-) Seems like the turbine is working pretty good indeed. Pitot entry was positioned between the turbine and half way of jet pipe. The S300 freepower turbine has a big A/R close to 1.30 if I remember right, that should take approx. 30lbs/min flow with our current nozzle pressure. If we can use a higher pressure for a freepower it could flow over 35lbs/min which is almost what our turbine produces. I think we'll also cut that S300 into half and remove the rib as our welds are still holding in the gas producer's housing.. What do you think John, should we use that maybe with a slight by-pass? Also what's the best rpm range for the freepower turbine.. There's plenty of planetary gears available from 2:1 to over 50:1 ratios, rated for only 8000rpm input but a little over revving can't be that bad  Output rating of 60Nm should be enough, those bigger frames tend to be too expensive.. I was thinking to try revs up to 50,000rpm and about 20:1 ratio gear. We'd get some speed for the turbine wheel right from the start  |

|

|

|

Post by racket on Mar 24, 2014 16:36:30 GMT -5

Hi Miuge Yep, all the numbers are well within the range they should be , I had to use a lowish turbine efficiency to get the numbers to align but not an excessively low number , maybe several percentage points but again well within "normal??" smallish turbo efficiency ranges. I'll do some numbers on the S300 to see what I can find . Your theoretical 27 lbs of thrust could produce ~25 -30 hp , this is well within karting horsepower numbers, so it'd be possible to use racing karting chain running up to 20,000 rpm at the "motor" , a smallish 2 or 3:1 gear ratio on the freepower would get your rpm low enough to use karting chain, with a larger gearing reduction the torque output would start to exceed the karting chain's limits, other , heavier chain, will need a greater reduction ratio due the chains lower rpm capabilities , so try to design for karting chain and sprockets wit a small reduction or heavier bike chain with a greater reduction . You'll need to think about your desired top speed and work back from that , 25 hp would be able to produce ~150 kph in a suitable chassis , but you might want to gear for a lower speed with better acceleration , my two shaft kart jetandturbineowners.proboards.com/thread/40/2-shaft-turbine-kart-build had ~30 hp and was able to use direct karting chain drive without a gearbox I'll get back to you with the freepower numbers :-) Cheers John |

|

|

|

Post by racket on Mar 24, 2014 22:19:47 GMT -5

Hi Miuge The Garrett Gt3782 turbine wheel is 72.5mm inducer with an 84 Trim , so the exducer outlet diameter is ~66.4mm , to get a comparable 72mm exducer diameter to your S300 we need to look at the www.turbobygarrett.com/turbobygarrett/turbocharger#GT4294 , this turbine wheel is ~10% bigger outflow area than yours with a ~75mm exducer vs your 72 mm , so we'll make a rough adjustment , lets use the 1.28 A/R line on the turb map at your jetpipe PR of ~1.4 , it gives a correct flow of ~36 lbs/min , unfortunately your ~40 lbs/min "actual flow" at 650 deg C with a PR of ~1.4 equates to a corrected flow of ~51 lbs/min , the S300 is going to be ~40% undersized :-( A 40% reduction in your horsepower is too much , you'll be back to ~18 hp , a larger turbine wheel is required to maximise your output , otherwise you'll need to fit a "dump" pipe and jetnozzle out of your interstage ducting , the jetnozzle will need to be ~32 mm dia . Hope this helps :-) Cheers John |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 25, 2014 2:49:24 GMT -5

Hi John, Okay, that's pretty much what I was expecting  Didn't notice those Garrett turbine dimensions were inducer diameters.. So it's not good to rise jetpipe PR? Does it cause too much temperature rise or choking the gas producer? Your calculations definitely help to perceive and develop our assembly. We still might go with the S300 first, and adjust the dump pipe size when things are bolted together. 18hp is a good start for the purpose, our baseline was to make it move... :-D I've done some gear ratio calculations for our desired 120/80-12" wheel: Freepower turbine 50,000rpm (or 25,000rpm and 10:1 reduction) Planetary gear 20:1 -> 2500rpm 13/45 sprockets -> 700rpm = 63kph 17/45 sprockets -> 900rpm = 86kph Freepower turbine 75,000rpm Planetary gear 20:1 -> 3750rpm 13/45 sprockets -> 1070rpm = 96kph 17/45 sprockets -> 1420rpm = 127kph Freepower turbine 50,000rpm Planetary gear 30:1 -> 1666rpm 13/45 sprockets -> 476rpm = nothing to mention..  17/45 sprockets -> 640rpm = 57kph Have to keep an eye on eBay to get a suitable planetary gear. 10:1 reduction might be a good investment as it would take 25,000rpm easier than greater reductions would take 50,000rpm.. Slower acceleration, but much more reliability and margin for freepower rpm rise.. |

|

|

|

Post by racket on Mar 25, 2014 3:19:01 GMT -5

Hi Miuge

Yep, any attempt to raise the jetpipe pressure will also raise the temperature , the lowered pressure ratio across the turbine will reduce its power , to compensate for this the temperature needs to be increased to restore the wheels power , also those higher temperatures could reduce the mass flow back closer to the surge line, at present your "numbers" are "safe" , I'd stick with them until the bike is running .

I'll do some calculations for the S300 wheel to determine max rpm , probably tomorrow morning , its getting too late tonight for doing maths :-)

Cheers

John

|

|

|

|

Post by racket on Mar 25, 2014 17:42:29 GMT -5

Hi Miuge

It looks like you'd have gas velocities of ~900 ft/sec if the pressure drop (0.4bar) is split equally between scroll and turb wheel , so wheel tip speeds of ~750 ft/sec , so a 70mm dia wheel would potentially be spinning up around 60,000 rpm , this is very high and will exacerbate any gearing problems, you'll be needing pressure jet lubrication of gears and their bearings.

Before you start on the freepower have a bit of a think about whether or not you might want to make a larger engine in the future , and if so then using a larger freepower might be the way to go before building this smaller one ..............the freepower and transmission is a much bigger/more difficult job than making the gas producer .

Cheers

John

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 26, 2014 3:56:05 GMT -5

|

|

|

|

Post by racket on Mar 26, 2014 15:30:04 GMT -5

Hi Miuge

Do you guys have access to a lathe , and the capacity to turn something up thats ~150 - 200 mm diameter . ??

There could be a "novel" solution to this if we think a bit laterally :-)

Cheers

John

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Mar 26, 2014 16:05:55 GMT -5

Okay, sounds interesting.. Yes we do have access to a lathe and CNC milling machine, but not constantly, secondly our machinist has a very limited time what makes creating things from scratch harder. It takes no time if I just draw a model for him.  Could you perhaps reveal your solution? I was already thinking to make an axial fan by welding, but after a while found myself searching for a huge turbochargers again. I'm hoping to make a deal of one S500 turbine shaft..  |

|