|

|

Post by stoffe64 on Apr 30, 2014 4:49:34 GMT -5

very nice work , i really appreciated the video, it looks so simple!

cheers/stephan

|

|

beaker

Member

Joined: March 2014

Posts: 18

|

Post by beaker on Apr 30, 2014 5:38:55 GMT -5

Looks like things are getting interesting. Dam its fun to experiment!

Keep up the good work.

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Apr 30, 2014 9:00:37 GMT -5

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on May 7, 2014 16:45:52 GMT -5

Finally we continued the turbine housing manufacturing.. Had some delay because our machinist was sick, but here's the part2 (should be online soon): vimeo.com/94456913Turbineshaft wasn't quite straight, not even close, noticed just when we put it into a lathe. Few punches with a sledgehammer made it better so it could be turned, then camera run out of battery so I didn't get any good footage. youtu.be/XDUwuYAUVGM |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on May 9, 2014 14:44:58 GMT -5

Blah, what do YOU think of the housing? I'm not sure if it goes to trash can or should I continue with it?  Yet it would be easy to change it..  |

|

|

|

Post by Johansson on May 9, 2014 15:30:46 GMT -5

Looks very nice! Did you make separate patterns for every segment or did you make a bunch and trim them to size?

|

|

gidge348

Senior Member

Joined: September 2010

Posts: 426

|

Post by gidge348 on May 10, 2014 9:16:39 GMT -5

I think that is fine, probably not flow as well as a factory cast one, but it may not have to ....I would use it.

When you think about it a lot of 2 stroke exhausts and pulse jets use the same technique so cant see why it wouldn't work?

Good job....

Cheers Ian..

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on May 10, 2014 11:36:11 GMT -5

Okay, I was worried about sharp corners and didn't like the looks.. So I started to create something more traditional:  |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on May 10, 2014 17:10:06 GMT -5

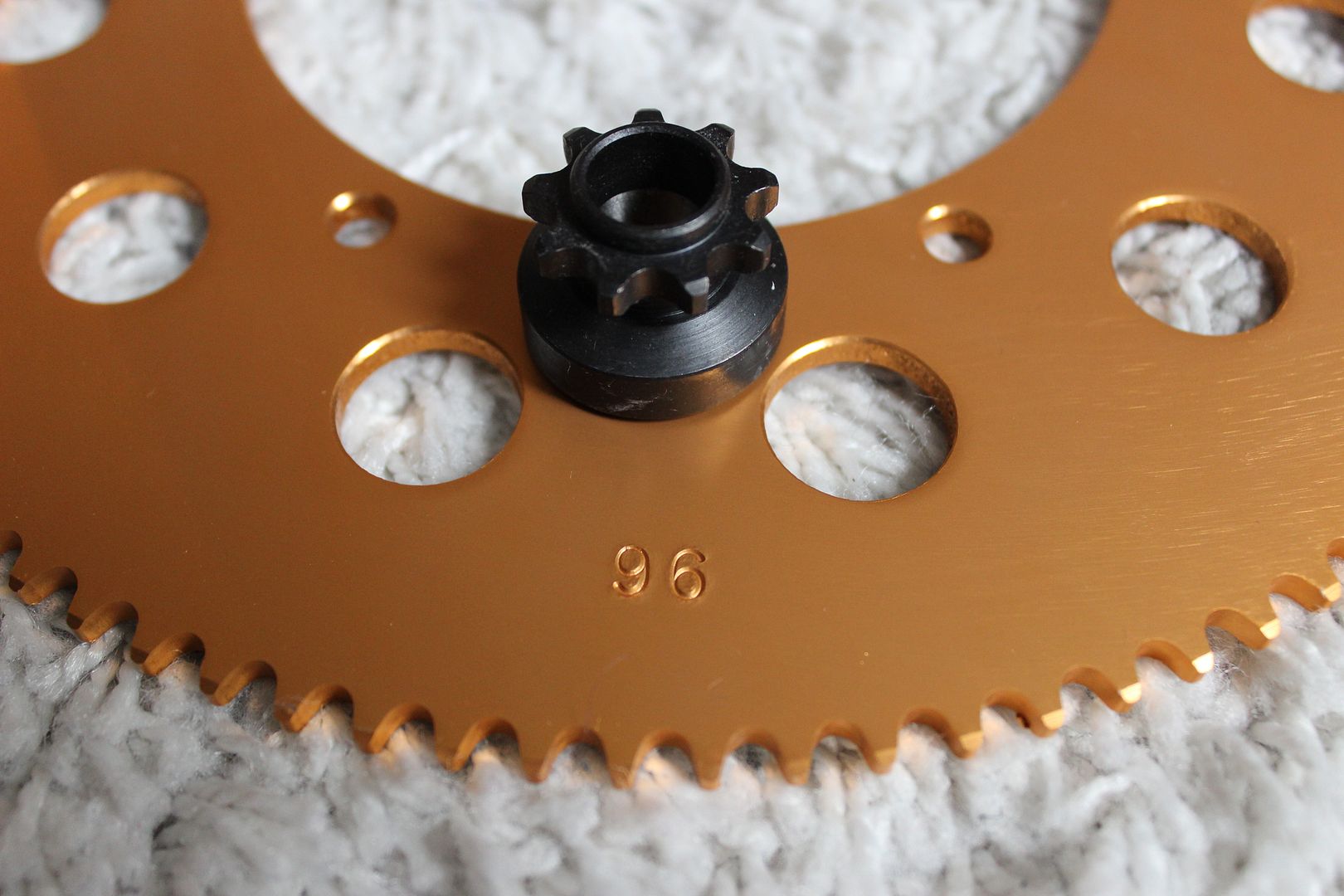

Sorry for the new post, but here's a new video of housing manufacturing: vimeo.com/94780562Also we got the sprockets 9 front and 96 rear:  |

|

|

|

Post by stoffe64 on May 11, 2014 2:37:36 GMT -5

damn what a nice work youre doing there!!, myself is fighting constructing the flametubes transition duct AND im stucked on that part.

|

|

|

|

Post by Johansson on May 11, 2014 4:53:36 GMT -5

I think the circular scroll looked much better than a sheet metal scroll, I´ll make a circular one for the boat motor.

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on May 12, 2014 11:41:13 GMT -5

|

|

|

|

Post by Johansson on May 12, 2014 12:33:01 GMT -5

Progressing nicely! Don´t be too sure of that, I haven´t got time to make this build top notch so I am perfectly glad if it looks half as good as yours.  Cheers! /Anders |

|

|

|

Post by racket on May 12, 2014 17:23:54 GMT -5

Great to see you guys had the good sense to make the "centre" part of your scroll out of some solid metal before welding on the sheeting bits , when I made my scroll for the two shaft kart I was too concerned with weight and had nothing but problems making the scroll from thin section material , .............LOL, it was thrown into the waste bin several times during its construction, only to be dragged out a couple of days latter to be resurrected , the distortions from welding were causing the turbine wheel to scrape the shroud, requiring some less than precision grinding using an old cutoff disc in the drill press :-(

Looking good :-)

Cheers

John

|

|

metiz

Senior Member

Joined: April 2011

Posts: 297

|

Post by metiz on May 12, 2014 18:58:17 GMT -5

It's a pitty you had to throw away the segmented scroll, but I love how you build it! very ingenious. I would have made every single part from sheet steel, would've taken forever!

|

|