|

|

Post by smithy1 on Jan 8, 2017 18:40:16 GMT -5

That's great work there Feathers....well done to all involved...I feel rather inadequate now...all my engine controls are "old-school" mechanical....no electronic aids to be seen..!

Cheers,

Smithy.

|

|

Feathers

Veteran Member

Joined: August 2010

Posts: 169

|

Post by Feathers on Jan 9, 2017 15:02:20 GMT -5

Thanks for the encouraging words. Smithy, your mechanicals don't glitch, you don't have to debug them or spend hours scratching your head over an end bracket }  What do you guys consider high oil temperature? We're keeping it below 200*F. Our only concern is the plastic end-cap on our pump. I'm thinking about asking Miuge and the guys at magnus racing if we can purchase their very slick oil pump end cap. I see they've moved on to larger projects. If not, we can machine our own, it will just take some time. Sending off for parts to be cut today! Hopefully that goes well. Thanks, - Feathers |

|

|

|

Post by racket on Jan 9, 2017 16:36:18 GMT -5

Hi Feathers

200deg F is probably getting a tad high if thats the temp going into the turbo from the oil tank as there'll be anything up to another 80 F degrees added when going thru the turbo making for possibly 280F coming out which could be degrading the lube somewhat, even synthetic lube , a temp of ~150-160 F going in is probably a more "accommodating" temp if this is possible .

Cheers

John

|

|

|

|

Post by smithy1 on Jan 9, 2017 17:34:15 GMT -5

Hi Feathers,

Don't you believe it, I often sit scratching my head when trying to nut something out....my brain cell has difficulty doing most things..! ;-) Mechanical is good for me, mainly because it either works..or it doesn't...simple.! John and I both believe in the "KISS" principle..!

What John said...I have an oil temp sensor at the pump outlet, which is not too far from the turbo inlet, possibly ~10" or so and I find it never goes over ~80C (176F) and I'm quite happy with that, the oil is in it's "zone" at those temps.

I do however have a decent sized oil cooler in the system which helps greatly....prior to fitting the cooler I found temps were heading quickly towards 100C (212F) and higher after longer or subsequent engine runs. I believe oil coolers are a must for longer run times, your engine bearings will thank you for it..

Cheers,

Smithy.

|

|

Feathers

Veteran Member

Joined: August 2010

Posts: 169

|

Post by Feathers on Jan 15, 2017 21:41:30 GMT -5

Hi Guys,

We measure our oil temperature at the oil outlet. So far we haven't seen over 200 degrees in the reservoir, before the oil cooler.

However, we have had very cold weather, and our runs have been short, so we might see higher temperatures in the future.

It has regular 0w-30 oil in it right now. We have 10 quarts of 0w-40 full synthetic for it whenever we get to changing it.

Our oil system has a relatively small reservoir (not more than 3 quarts capacity) but a large radiator. Hopefully this will help. If not, we need more fans!

Thanks,

- Feathers

|

|

|

|

Post by pitciblackscotland on Jan 15, 2017 22:15:32 GMT -5

|

|

Feathers

Veteran Member

Joined: August 2010

Posts: 169

|

Post by Feathers on Jan 19, 2017 2:32:08 GMT -5

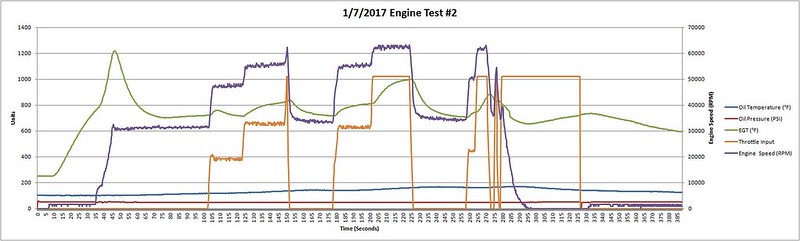

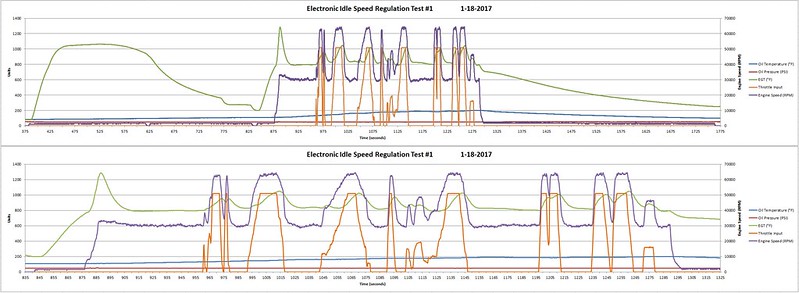

Hi Mark, For now, our turbo outlet oil temperature is below 200*F. This is okay with us. Soon we'll have our turbine housing ceramic coated, and we'll see what kind of difference this makes as far as equilibrium temperature. We've implemented a new feature into the firmware the kart runs! Its called Electronically Regulated Idle Speed (ERIS). This is code which solves the problem of engine idle speed drifting up as oil temperature increases, in journal-bearing engines. In our latest test, we ran the engine from an outlet oil temperature of 100*F to 200*F (inlet roughly 50*F lower), and the idle speed remained solid at almost exactly 30,000 RPM. Here is a run without ERIS:  Here is a run with ERIS:  This should keep our turboshaft vehicle from getting "restless" when the oil warms up and idle speed increases  You might notice the warmup and cooldown periods. Both are indicated by an engine speed of 1500 RPM. Warmup is indicated by an EGT of ~1000*F. The "verbose" top chart of our latest run (ERIS test) shows a warmup and cooldown cycle before the engine starts. The warmup cycle "timed-out" (took too long) waiting for the oil to reach operating temperature, so the engine defaulted to the cooldown state (lower EGT and oil temperature to acceptable shutdown levels). This often happens when the engine is cold, or our starting fuel cylinder is cold. Till next time, - Feathers |

|

Feathers

Veteran Member

Joined: August 2010

Posts: 169

|

Post by Feathers on Jan 21, 2017 4:23:16 GMT -5

Hi Guys,

What ceramic coating would you recommend for the inside of the turbine scroll?

We really want to keep heat transfer to the scroll and CHRA to a minimum, in order to lighten the load on our oil cooling system.

Cerakote sells Insulkote (W-209Q), which is intended to provide an internal thermal barrier to exhaust components, at temperatures up to 1800*F.

What have you all used successfully? Is it worth it?

Thanks!

- Feathers

|

|

|

|

Post by Johansson on Jan 21, 2017 5:23:24 GMT -5

I have used Weird Performance´s TurboX ceramic coating on the JU-01 mild steel NGV and turbine housing with great results, I don´t know about the degree of thermal insulation but it is still there despite years of abuse. I assume any quality brand of ceramic header coating will do, just make sure that you clean the parts properly and sand blast them with new sand to give the surface a rough texture for the coating to stick to. No glass beads since the surface will become too smooth.  Also make sure to heat treat the parts according to the instructions after the coating has been applied, before heat treatment the coating can be scratched off with a fingernail so it is very brittle, after heat treatment it becomes very hard.  After a couple of runs the coating turns a bit grey but the only section that has come off is the thin NGV vanes, most likely since I couldn´t reach them properly with the sand blaster.  Cheers! /Anders |

|

|

|

Post by jetjeff on Jan 21, 2017 7:46:54 GMT -5

WOW, does that look nice.

Regards

Jeff

|

|

Feathers

Veteran Member

Joined: August 2010

Posts: 169

|

Post by Feathers on Jan 22, 2017 5:07:03 GMT -5

Those parts look wonderful...

Hopefully we can achieve the same results. Cerakote makes a compound intended to coat internally and reduce heat transfer into exhaust components, so we'll give that a shot.

Looks like we'll need a good oven. Should do alright putting it in a conventional oven on the "clean" cycle... That makes it up to 700 or 800 degrees...

Thanks for the feedback!

- Feathers

|

|

Feathers

Veteran Member

Joined: August 2010

Posts: 169

|

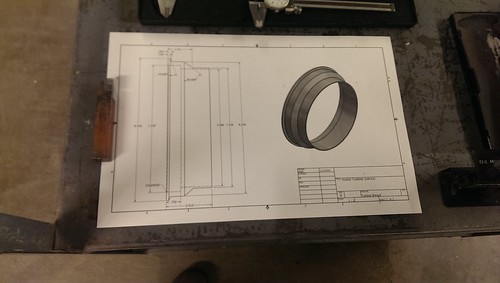

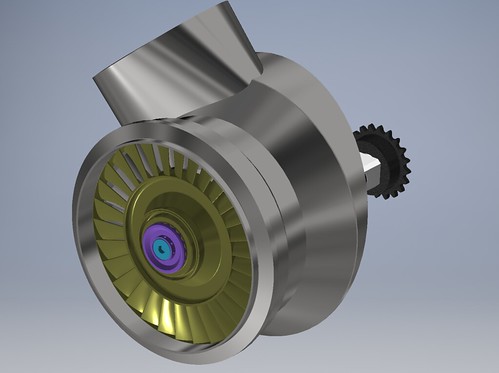

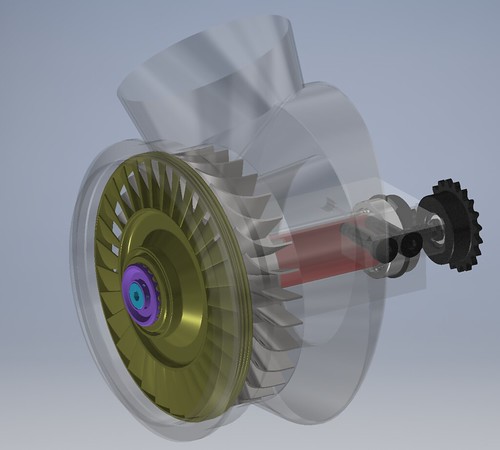

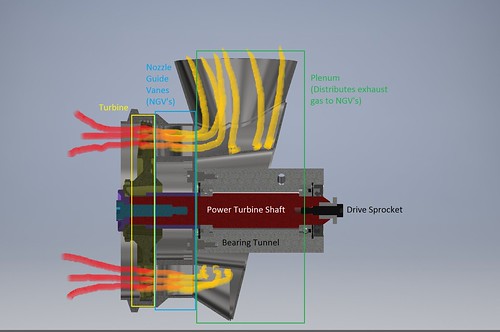

Post by Feathers on Jan 25, 2017 3:46:22 GMT -5

We started work on the power turbine shroud today. Started with 1" thick 8.5" OD Hollowbar steel stock.   It took me 8 hours to pull that part out of a big chunk of steel. I don't know where you guys get the patience to manually machine all these large pieces.  The turbine shroud is finished. Hopefully you can see where it fits into the power turbine assembly: (Hopefully the flow areas in the plenum look adequate. I ran some maths, which I've now forgotten, that indicated to my handful of brain cells that the design was okay.)    Cheers! - Feathers |

|

|

|

Post by pitciblackscotland on Jan 25, 2017 4:11:15 GMT -5

Hi Austin,

LOL i get my patience by stuffing things up and then i have to slow down so i don't make the same mistakes again.

Keep up the good work, in time you have the parts machine out.

Cheers,

Mark.

|

|

|

|

Post by Johansson on Jan 25, 2017 9:18:44 GMT -5

Hi Feathers, What, you don´t fancy 8 hours in front of the lathe?? You are a strange strange man...  If I were you I would design the power turbine plenum so that the incoming gasses enter at an angle and give a pre swirl to make the gasses enter the NGV easier, the smoother the gas path the better. Now it looks like the gasses will have to do a 90 degree bend to enter the NGV, far from optimal IMHO. Make the plenum more like a turbo scroll with the entry at the tangent and a narrowing duct that wraps 360 degrees around the NGV, checkout Johns work in Andrews jetbike thread: jetandturbineowners.proboards.com/thread/34/motorcycle-project?page=6Cheers! /Anders |

|

|

|

Post by racket on Jan 25, 2017 17:31:12 GMT -5

Hi Feathers

LOL.................machining bits outa ordinary steel is the easy stuff, its those large stainless bits I hate doing , hours of squealing tool bits and those long curly bits coming off just waiting to wrap around your hand and surgically remove it in an instant :-;

Your parts are looking good, I agree with Anders , try not to have sharp changes in direction with the gases , a large volume scroll with relatively low gas speeds will "pre swirl" the gases before they encounter the NGV vanes , which can be made with less "bend" to accommodate the preswirl, with my freepower scrolls they're more like a normal scroll with a single inlet "throat" that produces the required pressure drop and gas velocity increase , the gases simply swirl around the ever decreasing cross section and are "forced" through the half dozen straight supports aligned at the "design" inlet gas angle, no NGV required , though its less efficient that a NGV stator due to more metal being exposed to the high speed gases.

Cheers

John

|

|