|

|

Post by pitciblackscotland on Jan 11, 2016 16:37:11 GMT -5

Hi John, Maybe it was put there as not to be reused? I have a brand new 4th stage wheel which look like it was drop had a ding on the side of the wheel. Cheers, Mark. Yeah...when our customers want their unserviceable/time/cycle expired Allison/RR-250 wheels back, we cut them with an angle grinder so they can't be re-used...Unfortunately this doesn't happen in some countries.....there have been horror stories over the years where so-called "dead serial numbers" re-appear in another so-called "serviceable" engine....usually in third world countries. With the online tracking systems we have these days, a dead serial number is red-flagged pretty much straight away. CASA are right on top of it here in Aus. I have a couple of "cycle/time expired" 1st, 2nd, 3rd & 4th C20B wheels at home, also have a complete "unserviceable" compressor rotor (minus impeller), essentially a complete C20B/B17 rotative assembly. Cheers, Smithy. Hi Brett, there was a flood of Allison turbine wheels on ebay years ago, I got my share of some wheels have a 4th stage that has been polish up looks nice. This site sells AR turbine wheels just type in the part number and it shows up wheels that are for sale www.partslogistics.com/Cheers, Mark. |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Jan 22, 2016 4:06:13 GMT -5

Hi,

I kind of discarded the idea about turbocharger based engine, too much weight because of the cast iron comp cover and watercooled chra.. This wouldn't be the most compact solution neither.

So I started thinking about John's suggestion again.. I got a turbine wheel catalogue from the seller of billet comp wheels, biggest turbine wheel in catalogue was GT60 113/130mm 11blades.. What would be a matching wheel for that?

-Mikko

|

|

|

|

Post by racket on Jan 22, 2016 5:10:02 GMT -5

Hi Mikko

There are a couple of Gt60 turbine wheels , the 113/130 you mention and the 119/130 of the GT6041 , the 113/130 which is used on heavy earthmoving equipment has a smaller tip height and is normally mated up with a comp wheel with less flow than a "competition" GT6041 comp which has a 106mm inducer .

The GT6041 has a boreless screw on comp wheel, so you'd be needing a wheel to suit , I'd imagine the 113/130 turbine wheel would need a similar screw on comp .

The KTS catalogue has a couple of billet screw on wheels , one at ~98mm inducer 141 exducer which is the same size as our TV94 comps , and a 104mm inducer 141 exducer , but this is smaller than a GT6041 comp wheel inducer.

Theres not much choice with screw on wheels , much more with bored wheels that slip onto a quill, and is the reason Anders and I are persevering with the TV94 turbine wheel for our engines , the wheel is also relatively cheap compared to GT60 wheels.

The GT6041 turb wheel is a nice big wheel , but I doubt you'll find a comp with any bigger inducer than the standard 106mm unit .

Cheers

John

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Jan 31, 2016 5:36:24 GMT -5

Hi, Okay thanks for the answers! I have to keep on searching for a better suitable combination, the simpler the better... I just happened to buy a 3D printer, we'll see if I could use it too in the next build  -Mikko |

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Dec 20, 2016 5:04:55 GMT -5

Hi everyone, It's been about a year since my last post in this thread, nothing groundbreaking yet.. I've been learning to 3D print parts and things looking promising so far, now I'm sure I could utilize it in my next build. Some printing and welding pictures gathered on my "personal" fb page: www.facebook.com/mrttuotteet/Occasionally I've been searching for +100mm comp turbochargers, in fact I made a new inquiry today to see if we get any results.. Still thinking HE851 and HC5A -series (found some Garrett TV turbos too), but not going to buy a complete unit, just a chra or wheels only if available... a long term "micro" turbine, hmm...  |

|

mitch

Senior Member

Joined: August 2014

Posts: 285

|

Post by mitch on Dec 20, 2016 11:25:47 GMT -5

miuge,

excited to see that you are thinking about another project, your last project was pretty cool

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Dec 21, 2016 5:43:00 GMT -5

It was a quick project, also the first one, but I can't deny it was fun whenever it worked  I have found an Inco HX82 wheel for less than $200, it should be a good start if nothing better appears, anyway there's countless compressor wheel options for that shaft. |

|

|

|

Post by racket on Dec 21, 2016 19:34:18 GMT -5

Hi Miuge

Yep , plenty of HX 82 comp wheel options .

What are the turb wheels dimensions ??

Cheers

John

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Dec 22, 2016 1:50:37 GMT -5

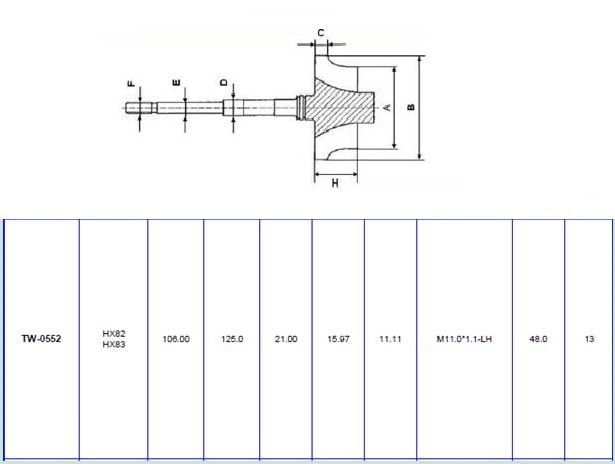

Hi John, I think that Inco 713C wheel is 125/106mm 13 blade based on the part number, K418 material wheels are available in 129/112mm dimensions, haven't found that bigger inconel variation.. Should I get a wheel for closer inspection to see what comp would be a good match?  Got the sheet for the inco wheel:  |

|

|

|

Post by racket on Dec 22, 2016 5:17:01 GMT -5

Hi Miuge

Thats about the same flow areas as the TV94 wheel we use , the TV94 wheel is ~129 mm inducer but a little smaller tip height than this wheel , exducer is the same 106 mm , so flow capacity will be roughly the same , so you could use a comp inducer up to ~106 mm like Anders is using in his JU-02 engine build .

Cheers

John

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Dec 22, 2016 7:27:52 GMT -5

Hi John, Okay that's good news! I've been looking at comp wheels in that size range, I don't want to take a risk using those "oversized" variations  There's 106mm comp wheels with both 141mm and 152mm exducer, smaller one being $100 cheaper. What kind of difference in power output are we talking about comparing these two? JU-02 seems to have X846 which is 106 x 152mm. |

|

|

|

Post by racket on Dec 22, 2016 16:24:31 GMT -5

Hi Miuge

The larger exducer has the potential for better high pressure efficiencies as the inducer tip speed is relatively lower than with the smaller exducer .

If you're only looking at running the usual 3 to 3.5 Bar P2 , then the smaller exducer will be OK , as they're the dimensions of the GT6041 comp wheel, 106/141 mm.

But if running "normal" P2s , I think I'd be using something a tad less than the 106 mm inducer, maybe ~102 mm , unless the turb wheel exducer is clipped to increase its flow as Anders wheel is as standard, certainly don't go any bigger than the 106 mm , if you want a simple build :-)

Cheers

John

|

|

Chuks

Senior Member

Joined: August 2015

Posts: 498

|

Post by Chuks on Dec 22, 2016 18:01:59 GMT -5

Hmmm!!!

Good to hear the TV94 turb won't need turb clipping for a smaller "102 inducer" compressor.

That precision grinding isn't just safe for we beginners.

Will definitely use the thrusty tv94 turb with the x855 compressor...number 500 in the kts catalogue.

|

|

miuge

Veteran Member

Joined: March 2014

Posts: 200

|

Post by miuge on Dec 22, 2016 18:20:37 GMT -5

Hi John, Well I have to think about if it's worth going higher PR or not. There's no ultimate goals for the project nor budget defined, but usually I try to save the last penny wherever possible  Price for the 129/112mm turbine wheel was just a tad over $100... Now that I tried to google about K418 material it seems that's equivalent to Inco 713C? Or just "chinese equivalent"? Then, while I stuck looking at 106mm comp wheels, X856 seems to be similar to Anders' X846 but has 3mm more tip height. Does it have more flow but less PR capability? Moreover about the design I'd like to do a combustor surrounding the exhaust, HX82 shaft being very short that way I could add some length and ensure proper combustion. Also had an idea of oil burner nozzles spraying fuel into evaporators after seeing "problems" with syringe needles.. I remember someone here had two inline fuel pumps in series? Does it multiply the pressure as supposed to by the theory or is there some restrictive factors? |

|

|

|

Post by racket on Dec 22, 2016 19:15:43 GMT -5

Hi Miuge

The bigger tip height sorta indicates a lower pressure ratio design as they try to design the comps for a roughly consistent flow velocity into and out of the wheel , the increased flow area at the exducer allows the lesser density air to flow out whilst maintaining velocity and mass flow, the two maps would look different even though mass flow might be similar , but efficiency islands might change position vs rpm .

Unless you need higher PRs to maximise shaft horsepower from a certain mass flow then the larger tip height might provide a more "flexible" flow , the ratio of inlet to outlet flow area will come back from the >2:1 ratio of Anders wheel to a more normal ~1.5 :1 ratio similar to the Garrett GT6041 wheel ................wheel design/configuration is become more complex and use specific, especially in these billet wheels , whereas cast turbo wheels were more of a compromise wheel able to cover a wider range of uses.

Cheers

John

|

|