Post by cchange4us on Nov 5, 2019 3:16:50 GMT -5

Gday everyone,

First up i have to say this site is fantastic, i have been reading a bunch of threads and have been able to answer so many of my own questions. This place has been a great resource. Now that has been said, on to my project:

I have been wanting to build a hobby gas-producer/power-turbine arrangement for a few years, however due to time constraints i have had to put it on hold. Beginning in a short while i will have a fair amount of free time and i am taking the opportunity to begin the build of my first diy gas turbine project. Looking forward it is my goal to create a combination which is compact, reliable and able to provide 40 hp at the power turbine shaft. I do however acknowledge that i should first be focusing on building the gas producer, optimising the combustion chamber and creating all of the correct supporting systems for such a producer. Below is a summary of the thoughts i have so far:

Which turbocharger to use - Admittedly, i have a bias towards holset diesel turbochargers as they are known for their reliability. I currently have a new and genuine holset HX35 sitting in my shed which from all of my reading appears to be an okay candidate for such a project. Straight away i can use the new HX35 to start building but for the first start up i will source a similar used HX35 and swap it over, just in case i mess things up! There are of course a few modifications that i will need to carrry out to the HX35 with one being the conversion to a single scroll turbine housing. I have read that the twin scroll inlet turbine housings have a tendency to soak up more heat than the single units which in my mind makes sense (more surface area as well as a large obstruction to flow which most likely causes turbulence). These conversion housings can be purchased on ebay (see below):

HX35 Turbocharger

Compressor:

54mm Inducer

78mm Exducer

Turbine:

60mm Exducer

70mm Inducer

Combustion Chamber and Flame Tube - I have toyed around with the JetSpecs calculator however as things progress i will be using some information i have read on this forum to calculate the desired dimensions, whilst of course also comparing it with Jetspcs. I want to treat it as an opportunity to learn more about the thermo and fluid dynamic aspect of gas turbines. For packaging sake, i am going to try and really optimize the efficiency of the combustor assembly and focus on controlling heat.

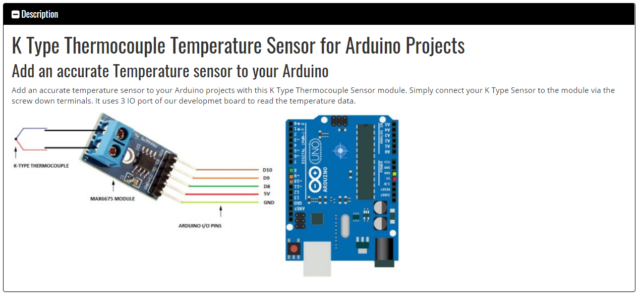

Electrical / Logic Control - I will use an Arduino Mega to take care of systems monitoring (sensors/readouts) as well as the starting/wind down process. I want to use a 24v DC system for powering everything. 24v because then it opens up the ability to adapt hobby brushless motors for various purposes. The brushless motor and controller packages appear to be a cost effective and compact way to provide power to various pumps and components, all whilst having the option to program some speed control into the motors if need be.

Fuel Supply - Initially i will use LPG for simplicity sake though once i get the hang of things i am keen to try out a high pressure diesel injection system controlled by the arduino somehow. I am attracted to the idea of a high pressure injection system because i can see how it would benefit the burn qaulity, i can also imagine it would make start up times quicker with less time spent warming up with LPG. However first thing is first so for now a simple LPG injection system will be constructed.

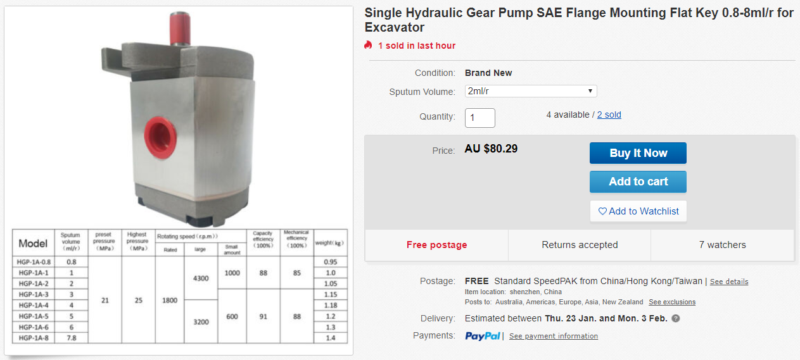

Oil Supply - I will use an electronic oil pump arrangement, either a modular unit that is completely off the shelf or a seperate pump/brushless motor combination so that i can use the Arduino to speed control the pump to account for viscosity changes/changes in turbocharger oil demand.

Starting / Shutdown - Of course in the short term a leaf blower will surfice however as things evolve i want to explore the idea of using a RC/hobby brushless ducted fan assembly. A system would need to be made that ducts the fans flow into the turbocharger compressor whilst starting and then opens the passage back up for running. What also excites me about this idea is that it can further be used to cool the engine after shutdown. A minute of getting fresh air shoved in its throat whilst still having the oil circuit flowing is ideal i think...

Power Turbine Section - Okay i am getting ahead of myself...

After i get the gas producer schmicko and take the resultant readings of outlet pressure and temperature i will turn my attention to extracting shaft power. For that i am thinking either a c20 Rolls Royce 2nd or 3rd stage turbine blisk and respective NGV. I can fabricate my own NGV if needed though. Im not sure of which reduction method is best yet so this detail can be decided on down the track. Its obvious that there are many, many things to be bought and built before i get to the power turbine section and hence i'll leave the discussion of it out for now.

I look forward to sharing my progress and by all means let me know what you think of my plan.

First up i have to say this site is fantastic, i have been reading a bunch of threads and have been able to answer so many of my own questions. This place has been a great resource. Now that has been said, on to my project:

I have been wanting to build a hobby gas-producer/power-turbine arrangement for a few years, however due to time constraints i have had to put it on hold. Beginning in a short while i will have a fair amount of free time and i am taking the opportunity to begin the build of my first diy gas turbine project. Looking forward it is my goal to create a combination which is compact, reliable and able to provide 40 hp at the power turbine shaft. I do however acknowledge that i should first be focusing on building the gas producer, optimising the combustion chamber and creating all of the correct supporting systems for such a producer. Below is a summary of the thoughts i have so far:

Which turbocharger to use - Admittedly, i have a bias towards holset diesel turbochargers as they are known for their reliability. I currently have a new and genuine holset HX35 sitting in my shed which from all of my reading appears to be an okay candidate for such a project. Straight away i can use the new HX35 to start building but for the first start up i will source a similar used HX35 and swap it over, just in case i mess things up! There are of course a few modifications that i will need to carrry out to the HX35 with one being the conversion to a single scroll turbine housing. I have read that the twin scroll inlet turbine housings have a tendency to soak up more heat than the single units which in my mind makes sense (more surface area as well as a large obstruction to flow which most likely causes turbulence). These conversion housings can be purchased on ebay (see below):

HX35 Turbocharger

Compressor:

54mm Inducer

78mm Exducer

Turbine:

60mm Exducer

70mm Inducer

Combustion Chamber and Flame Tube - I have toyed around with the JetSpecs calculator however as things progress i will be using some information i have read on this forum to calculate the desired dimensions, whilst of course also comparing it with Jetspcs. I want to treat it as an opportunity to learn more about the thermo and fluid dynamic aspect of gas turbines. For packaging sake, i am going to try and really optimize the efficiency of the combustor assembly and focus on controlling heat.

Electrical / Logic Control - I will use an Arduino Mega to take care of systems monitoring (sensors/readouts) as well as the starting/wind down process. I want to use a 24v DC system for powering everything. 24v because then it opens up the ability to adapt hobby brushless motors for various purposes. The brushless motor and controller packages appear to be a cost effective and compact way to provide power to various pumps and components, all whilst having the option to program some speed control into the motors if need be.

Fuel Supply - Initially i will use LPG for simplicity sake though once i get the hang of things i am keen to try out a high pressure diesel injection system controlled by the arduino somehow. I am attracted to the idea of a high pressure injection system because i can see how it would benefit the burn qaulity, i can also imagine it would make start up times quicker with less time spent warming up with LPG. However first thing is first so for now a simple LPG injection system will be constructed.

Oil Supply - I will use an electronic oil pump arrangement, either a modular unit that is completely off the shelf or a seperate pump/brushless motor combination so that i can use the Arduino to speed control the pump to account for viscosity changes/changes in turbocharger oil demand.

Starting / Shutdown - Of course in the short term a leaf blower will surfice however as things evolve i want to explore the idea of using a RC/hobby brushless ducted fan assembly. A system would need to be made that ducts the fans flow into the turbocharger compressor whilst starting and then opens the passage back up for running. What also excites me about this idea is that it can further be used to cool the engine after shutdown. A minute of getting fresh air shoved in its throat whilst still having the oil circuit flowing is ideal i think...

Power Turbine Section - Okay i am getting ahead of myself...

After i get the gas producer schmicko and take the resultant readings of outlet pressure and temperature i will turn my attention to extracting shaft power. For that i am thinking either a c20 Rolls Royce 2nd or 3rd stage turbine blisk and respective NGV. I can fabricate my own NGV if needed though. Im not sure of which reduction method is best yet so this detail can be decided on down the track. Its obvious that there are many, many things to be bought and built before i get to the power turbine section and hence i'll leave the discussion of it out for now.

I look forward to sharing my progress and by all means let me know what you think of my plan.