stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Aug 20, 2013 22:13:16 GMT -5

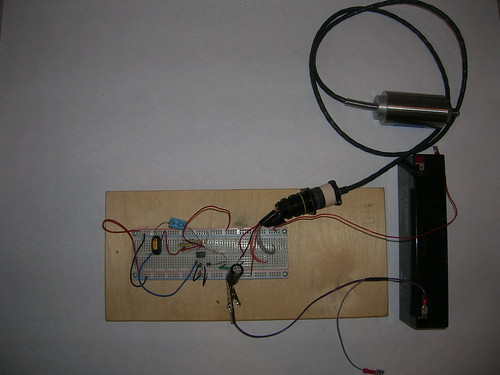

Pressure Transducers When I first decided to go ahead and build a liquid motor, I knew I'd need some pressure transducers. The source for the ones that I use with solid motors dried up, so I scoured EBay for some and found these:  They're very nice military surplus, 0-1000 psi (69 bar). The only hitch is that they take 28 volts which is an odd voltage--you don't find many 28 volt batteries lying around, which is probably why the transducers sell so (relatively) cheaply. They came with super-nice connectors on them, which turn out to be very expensive military grade. You can buy the mating connectors for $65-$75 (each!) which is a bit out of my league. But they were too nice to cut off, so, for all those months when I was playing with sprays and drop sizes, I was also pondering ways to make use of these connectors. I finally found some relatively inexpensive plastic circular connectors that I could make fit by turning them down a bit on the lathe. You'll think I'm nuts (and for a while *I* thought I was nuts) to go to such lengths but those connectors on the transducers are *very* nice--they're aluminum and the back sides are silicone-filled to keep out moisture and dirt. It would break my heart to cut them off, so the effort to find a way to use them was, for me, well worth it. The next part of the puzzle was that 28 volts. I'd already decided to go with a 12-volt sealed lead-acid battery for the rest of the electronics: they're cheap, I already have a charger for it, it will fit nicely in the same box with the electronics, and 12 volts is what the ignition coil requires. I could use a bunch of 9-volt batteries to get the 28, but then I'd have to deal with replacing them, or use rechargeable ones (and mess with yet another charger). That path just seemed messier than I wanted, so I explored using a DC-DC converter to go from 12 volts to 28. Did I mention that 28 is an odd voltage? Yup, not a lot of ready-made stuff creates 28 volts and most of what could be made to work (by, for example, converting to 36 volts and then stepping down) was pretty expensive because it was designed to supply a lot of power, which I don't need. So....I decided to build my own. Never done that before, I so I was a bit hesitant--seems like it could be the kind of thing that would be messy, picky, and difficult to get right. My hesitation was reinforced when I discovered that there are thousands of chips to base a design on--which to use? Finally, I just decided not to bother trying to pick the best one, and just selected one that seemed to be the focus of a lot of chatter on the net so if I ran into problems, there'd be places to go for help. Turns out that once you have the ten required parts, four of which came from my spare parts box and the others obtained locally, that it's *easy*! Fifteen minutes of breadboarding and I had 28 volts with enough current to run all four transducers! A few hours of fine-tuning and experimenting just to see what I could make it do, and I think I have a usable design. Total cost is about ten bucks. Here's the breadboarded version running one of the pressure transducers:  I had concerns that the output of the DC-DC would be too noisy for good data collection, but the pressure transducers seem to handle it quite easily--so far the output looks very clean. So I connected the ignition coil assembly to the battery, put the scope on the output from the pressure transducer, took a deep breath, and fired up the igniter. The output looked fine, but the real test is to hook it up to an analog-to-digital converter and see what happens. --Steve |

|

wolfdragon

Senior Member

Joined: April 2011

Posts: 287

|

Post by wolfdragon on Aug 21, 2013 18:20:17 GMT -5

Looks like you have a substantial amount of capacitance on the input and the output, add a 0.1uF capacitor across the pins that the chip uses for internal power and that should make doubly sure that you don't have noise issues, you want this capacitor as close to the chip as possible.

|

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Aug 22, 2013 9:28:40 GMT -5

Good eyes, Wolfdragon! It's on my hand drawn schematic, but in my eagerness to get the thing going I just forgot to stick in on the breadboard. I'll add it today....

--Steve

|

|

|

|

Post by turbochris on Aug 22, 2013 20:39:43 GMT -5

they prolly say 28 v for aircraft use. If the output say 0-5 volts they'll probably work on 12 volts

|

|

rexhunt

Member

Joined: August 2012

Posts: 32

|

Post by rexhunt on Aug 22, 2013 21:19:27 GMT -5

I think you're onto something Chris, I remember my brother saying something about in a light aircraft at least they use 28V

|

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Aug 22, 2013 21:48:08 GMT -5

Re the 28 volts, I had hoped when I bought them that they'd be ratiometric--that is, feed them half the rated voltage and you'd get half the rated output, which I'd be fine with because I don't need super precision. So I tried them on 5 volts, just for fun--no output. Tried 12v--no output. Figured the spec of "Input: 28-30 volts" meant what it said, so did the DC-DC thing. Just for a little more fun, and while I was playing with the different voltages the DC-DC can make, I tried the sensors on 20 and 25 volts--no output. They really do want 28 volts. Output is 0-5 volts.

--Steve

|

|

|

|

Post by turbochris on Aug 23, 2013 8:56:55 GMT -5

watch dog on input voltage. They'll shut up before they lie. your voltage converter is the best solution that I can see if they're that picky.

On that note, I'm looking for something to convert 14 volts to 26 volts few 100 ma to float charge the start batteries for the turbine in my van. Care to share your schematic?

|

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Aug 23, 2013 15:04:41 GMT -5

The chip is the TI MC34063, the schematic is right out of the data sheet (Fig 6, "Step Up Converter"), but you need to do a few calcs to get the values for a specific voltage/current. There is a handy online calculator here: dics.voicecontrol.ro/tutorials/mc34063/ The exact values aren't that critical; I started with the standard values closest to what the calculator gave. For example I went with a 50KHz oscillator frequency, the calculator said 504pF for the timing capacitor, and I used 470pF. The output voltage is set by the voltage divider formed by R1 (10k), R2 (220K). The inductor ("L", 100nH, more than I need) and Rsc (1 watt, 0.10 ohm) have to be sized to handle the input current--the parts I could get easily were good for over 1 amp; smaller physical sizes are possible if you are tight on space. Rsc controls the output current--I'm able to pull over 600mA without the voltage dropping more than 100mV or so. My output cap is 1000uF, my input cap is 100uF. I'm not using the optional output filter shown on the data sheet. The calculator has a link to a youTube demo of how to put one of these together--it's a bit long, but it covers all the calcs in detail. Or, you can just study the data sheet--there's a table of calculations near the back. I finally ended up just making some small tables for the various components so I could see how they depended on frequency, current, ripple, etc. I think that covers everything...if you want more, just ask. --Steve |

|

|

|

Post by turbochris on Aug 24, 2013 7:39:44 GMT -5

got it from here! thx!

|

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Aug 25, 2013 7:39:14 GMT -5

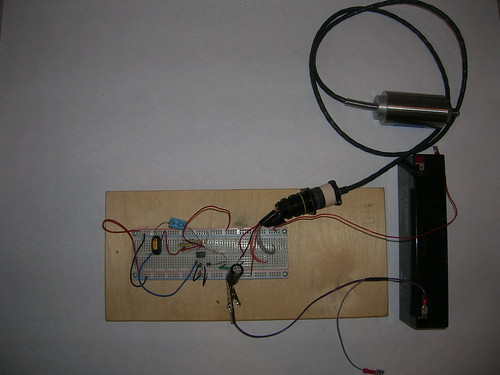

The master control The data collection/control system I'm building has at least two micro-controllers and while I don't yet know all the details of how the main micro needs to be connected, I need something to test with in the meantime. So I built myself a small development version that has sufficient flexibility to test all the other planned boards either singly or in combinations. Here it is:  This is just a clone of a board I've used for past projects, so it went together fairly quickly. The micro is in the middle (PIC 16F877 or 16F887, 5v, 20 MHz), there's a small LCD, some memory, an RS232 interface, and plenty of pins for I/O. So far, so good. A while back I'd done back-of-the-envelope calculations as to how much data I'd be collecting and how frequently I'd need to sample the various sensors. To collect data at a rate similar to what I've used for solid motors looked pretty straightforward. I wanted to make use of chips, software, and techniques that I'd used before since it would go faster than if I used a bunch of technology I'd never used before. Doing some of this stuff from scratch can take *weeks* to iron the bugs out, and I didn't want to spend time doing that if I could help it. I wanted to be free to focus on stuff (like the igniter and valve control) that were new to me and re-implementing stuff I'd used on other projects would allow me to do that. As it happened, as I was putting the development board together, the aRocket folks exchanged a few messages about data collection which got me thinking about detecting combustion instability in liquid rocket motors. This is a huge subject in professional rocketry and has historically caused enormous problems, especially with very large liquid motors. My solid motors have been small and use a very stable, well-characterized propellant, so I haven't had to deal with this issue. My solid motor data collection system samples at a leisurely rate of 100 Hz from one pressure and one thrust sensor (200 samples/second total). It's been more than adequate and basically consists of a board similar to the development board pictured above. It couldn't be much simpler. Liquid motors are a different kettle of fish. Combustion instability can result from uneven mixing, chamber resonance reinforcing the normal chaos of combustion, uneven feed rates in the propellant or oxidizer plumbing, and so on. These instabilities can vary in frequency from tens of Hz to thousands of Hz. To spot them, sampling may have to be done at rates of several thousand Hz. Worse yet, the commonly available pressure transducers (based on strain gages) don't respond any faster than about 500-1000 Hz; to spot an instability with a frequency any higher than about 500 Hz means switching to piezoelectric transducers which are not common on the used market, are hard to find when they're available, and brand new cost hundreds of dollars each. Ugh. Anyway, it is clear that collecting data at 100 Hz won't cut it if I run into instability issues. I don't need this ability to start with--first I have to get a motor to ignite. Then it has to run for at least a few seconds without melting down. After that I can deal with gross instabilities if they seem to exist. But I don't want to have to scrap the whole data collection and control system (or even major parts of it) if/when I upgrade, so I reviewed my design to see how just how fast it could be made to sample and what it would take to speed it up if I needed to. There are three major issues: 1) the amount of data that will be collected (and need to be stored), 2) the rate at which the storage medium can accept the data, 3) the speed of the inter-board communication bus that carries the data from the sensors to the micro that stores it. What is easy when dealing with one or two sensors at 100 Hz becomes *much* harder when dealing with six or so sensors at 1000 Hz, let alone rates much higher than that. A commercial system that will run at about 1000 Hz *starts* at $600. When I started looking at how to go from 100 Hz to 1000 Hz things got ugly pretty fast. For a while I thought I was going to have to scrap the entire design and use a different communication bus, totally different memory, different micros, etc. In other words, do exactly what I was hoping to avoid. I really, really didn't want to do that, so for the past week or two I've been acting like a rat in a maze, trying one path, then another hoping to find a way to use as little new technology as possible. There are lots of ways to do what I need, but they all involve complicated stuff I've never used before--and when a supposedly simple chip comes with 50 pages of documentation, you just *know* something's going to bite you. But after hours and hours of searching for products and reading documentation, things finally started to sort themselves out. I will have to use a different communication bus than I've used before, but it's one that lots of hobbyists use, it's relatively simple, and it works with my existing micros. I will have to use different a/d converter chips than I had planned on (a bunch of research down the drain there), but generally speaking, they're pretty similar in the way they work, so that shouldn't be a big deal (yeah, right). Then there's the memory capacity. The little 128K memory chip I use in my solid motor data collection system won't cut it at the higher data rates--it won't accept data fast enough and it doesn't have enough capacity. Turns out there's a similar chip that works with the new bus (good) and I can combine several of them to get the additional capacity I need. But they are slow like the one I was originally going to use. However, what I realized in a Eureka! moment was that having several of them also solved the speed problem: I can write small amounts of data to them in round-robin fashion, so that while one is busy storing data, I can be writing to the next one. When I next need to store some data, I can write to the one after that, and eventually cycle around and write to the first one again which, by the time I get back to it, will have finished storing the data I sent it earlier. So the memory problem looks to be solved fairly easily, too. It involves a bit of "bookkeeping" that I wouldn't have had to do when using just one memory chip, but it's simple enough for an experienced programmer. It is true that this only gets me to a sampling rate of 1,000 Hz for the six sensors but there's no point in making the system go faster than that because the sensors won't respond any faster -- by sampling faster, I'd just be getting duplicate data. If/when I need to go faster, it's going to be a major upgrade of at least one sensor and I figure I can make a board dedicated to that sensor and work that into the system. At any rate that problem looks to be far enough down the road that I'm not gong to think about it any more right now. I'll just build the system for 1000 Hz and deal with upgrades later. Needless to say, I am very relieved that I'm done redesigning things and that so little will have to change from what I originally planned on! The next issue was software. Fortunately, software is my profession and micro controller software is something I've been writing as a hobby for six or eight years now. Even more fortunately, I happen to have the basics of what I need: my solid motor data collection system is a subset of what I'll need for the liquid data collection system, and my flight computer that flies on the solid rockets also contains some useful bits. After a few hours of cut-and-paste I had about 800 lines of PIC assembler running on the dev board pictured above. This will form the basis of the ultimate data collection/control software, but for right now all it does is rudimentary data collection (one sensor), display, storage, and uploading the data to a PC. --Steve |

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Aug 31, 2013 18:29:51 GMT -5

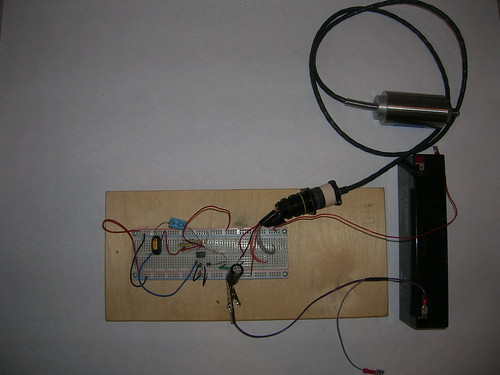

Before the design "crisis", I had ordered an a/d chip of the sort that I thought I was going to use and the other day it finally arrived. Even though it's no longer the same chip as I'll ultimately be using, it will suffice for testing until I can get the real one, so I built a small PCB for it:  You can just barely see the little black chip in there (yes, they're fun to solder!). I connected it to the development board and with some software tweaks managed to get it to accurately measure a fixed voltage. My next task was to measure the output of one of my pressure transducers to see whether the output was stable enough to use, given my hastily assembled dc-dc converter. I'm pleased to report that even though I'm measuring with a precision of one part in about 32,000, the output shows absolutely no jitter! That is far greater precision than I need, of course: 1/32000 of 1,000 psi is an amount much smaller than I will ever need to consider. But during the real test I may lose a bit of precision due to noise that isn't present right now, so having the extra is good. Over a period of a few minutes, the output from the pressure sensor gradually rose to a value about 0.2% (yes, two tenths of one per cent) higher than when the system was first powered up--I'm assuming this is due to thermal drift of various components. Such a small amount will be absolutely meaningless in the final scheme of things--0.2% of 250 psi (17 bar) is a mere 0.5 psi (0.034 bar)--I'll be happy if my combustion/thrust results are within 10% of design so having a measurement be off by half a pound here or there is no big deal. These measurements were taken using the calibration feature these sensors have built into them; I still need to do a rough check with real pressure to see that the calibration isn't off by more than I can tolerate. I don't need NIST standard, but I would like to know that they're close. For the time being, I'm a happy man! Next up: what does the igniter do to all this? --Steve |

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Sept 3, 2013 20:37:04 GMT -5

Igniters, micros, and pressure transducers

Once I had a baseline idea of how stable the measurements were in the absence of purposely introduced noise, it was time to see whether things would get fouled up with the igniter buzzing away.

This matters because I want to have the igniter start producing sparks, then open the nitrous and fuel valves. After that I want to use chamber pressure to determine when ignition has occurred. If the controller sees a big jump in chamber pressure, it will know to a) turn the igniter off, b) allow the test to continue. If it doesn't see the jump after a few seconds, it will close the valves, shut off the igniter, and end the test. If the igniter creates too much noise, the controller will never detect the rise in chamber pressure (or, perhaps worse, think ignition happened when it didn't). And, obviously, if the igniter fouls up the electronics, opening the valves in the first place will be problematic.

Now it occurs to me that liquid motors are loud enough that it should be pretty evident to *me* whether ignition has taken place (or not) and I could manually proceed or not based on that. However, I've done enough tests that I'm not sure I trust myself to quickly press the right buttons in the right order during all the excitement, so I'm thinking it will be better to leave it up to the software/hardware to do it. And, besides, I still have to start the igniter and *then* open the valves, so I need to solve the noise problem (assuming it exists) anyway.

This igniter-fouling-the-electronics was part of my concern when I was deciding whether to use electronic or pyrotechnic ignition. Pyro would be completely compatible with the electronics, but seemed like it would be harder to get working in the first place, might be inconsistent from one igniter to the next, and not be nearly as convenient to use. Pyro is used by folks to start nitrous hybrids; electronic igniters have been used by many with liquid motors without destroying their electronics, so each can be made to work. For me, electronic was fairly easy to try out and early tests seemed to indicate that I'd made it "quiet" enough to not foul things up too much. However, I hadn't yet tried it with *digital* electronics. It was now time to do that. Oh, did I mention that delicate electronic components generally don't like sparky things near them?

First, I tried it with just the micro and the display--no A/D converter, and especially no pressure transducer. If a random high-voltage spike was going to kill something I wanted it to be something relatively cheap and easy to replace. On the first try, the LCD went nuts. Nothing fried, but I had to power off/power on to reset it. The micro appeared to keep running.

What follows is a drastically summarized version of about a week's worth of reading and experimentation. The scope showed random, very narrow spikes of about 5-20 volts getting through the voltage regulator. I'd thought the voltage regulator would have clipped them off, but it didn't. OK, add Zener diodes. Futzed with that *forever*, and seemed to make some headway--the spikes were still there, but lower in magnitude. This seemed to help the LCD, but when I tried out the A/D chip, it went nuts. I researched every blessed thing I could think of, but the pulses made by sparks are very, very quick (< 1 nanosecond in duration) compared to other things which, apparently, are measured in microseconds and even milliseconds. Finally I was forced to conclude that these spikes were just too fast for Zener diodes (and other similar products) to catch.

Running the sensitive electronics with a separate battery showed that the spikes were definitely coming through the wires, not the air, which was good in that if I had to, I could use (ugh) a separate battery to get around the problem. Didn't want to do that--that's why I built my DC-DC--so I wasn't going to give up just yet. The real problem (I think) is that my ignition coil is wired as most (all?) are: an autotransformer which means the secondary winding isn't isolated. So I thought about other approaches to making sparks (and which could be isolated), but concluded that I've got too much invested in this approach to discard it and start over with a whole new research project.

After concluding that Zeners weren't going to do the job, I tried adding capacitors of different sizes and types and finally found a combination that reduced the problem to *almost* zero. I could pulse the igniter dozens of times before just the right spike would randomly show up and confuse the A/D chip. Unfortunately, I don't think that's quite good enough--I can just see myself driving 7 hours to do a test and having it fail because the spike that happens only once in 20-30 times happens right then. Nope, not good enough :-)

My next idea was to beef up the voltage regulator that supplies the digital circuitry--right now I'm using an old, tried and true type of regulator that I've been using for ages, but there are better ones available (thanks, largely, to the massive amount of electronics going into cars these days), so I got one of the ones rated for automotive use and tried it. No joy.

My next idea is to hide the igniter circuitry behind a voltage regulator. Right now I run it straight from the battery since it wants a couple of amps and all the chips that form the igniter circuit run just fine on 12 volts. However, that lets the spikes out to roam where they will, meaning that I have to clobber them everywhere they cause problems. If I put the igniter circuit behind a beefy voltage regulator, that might corral the spikes a bit. The only issue is that to get 12 volts out of a voltage regulator, the voltage going in has to be a bit more than 12 volts. I found one regulator that's good for 3 amps and only requires about 12.5 volts in to produce 12 volts out. And, in case you didn't know, a lead-acid "12 volt" battery produces over 14 volts when it's fully charged, even under a bit of load, so I should be fine there.

Unfortunately, this will have to wait a while as I am about to head out of town for about 10 days.

--Steve

|

|

|

|

Post by ernie wrenn on Sept 4, 2013 13:26:49 GMT -5

Have you tried a Faraday cage to control any clutter or RF siginal ?

|

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Sept 22, 2013 19:36:33 GMT -5

Hey Ernie,

A Faraday cage won't work because the noise isn't coming through the air--the noise is already on the wires so there's no way shielding will keep it out.

--Steve

|

|

stevep

Veteran Member

Joined: November 2012

Posts: 120

|

Post by stevep on Sept 22, 2013 19:43:35 GMT -5

Voltage Spikes (still)

Short update: I'm still not out of the woods.

Longer update: The latest strategy was to hide the igniter behind a voltage regulator, the hope being that the voltage spikes wouldn't go "upstream" against it. The part arrived, but had no effect. I'm trying a few other things but they're long-shots, so I'm fearing that I may just have to bite the bullet and go with a separate battery. But I really really really don't want to do that :-)

========================

Valves

I swear, valves have got to be the hardest part of making a rocket motor! Seems like they give everyone problems and I'm no exception.

While I was waiting for the latest voltage spike part to arrive, I played with valve motor control. I breadboarded it and ran the little motor by itself (no valve). It went back and forth under microcontroller control quite nicely. Then I hooked up the potentiometer to see if I could get the motor to go a certain fraction of a turn and back. It took a bit of futzing, but that worked quite well, too. I have a resolution of a couple of degrees or so, which is more than good enough. My test program consisted of the microcontroller opening it fully, then after a few seconds backing it off to 1/2, then after a few seconds more, closing it. It was quite fun watching the thing go through its paces seemingly "by magic". Sorry I don't have video :-(

However, when I tried attaching a valve, things started to fall apart. You will recall that some time ago I had some light, but hard-to-mount valves which weren't made any more, and I had found an easy-to-mount valve which was heavier than I wanted but usable. First, I mounted the easy-to-mount valve. Everything looked good, the gears meshed nicely, the mount seemed secure, and so on. But when the motor tried to turn it, the gears unmeshed immediately! It turned out to be caused by slop in the valve stem and there's nothing I can do about it--that's just the way the valve is made.

OK, back to the old valve--and, by the way, I found a couple more that I'd bought years ago and used in various bits of gear I have lying around--I'll steal those valves for the rocket itself when the time comes. In the meantime, the old mount that I'd made for the valve wouldn't work with the potentiometer attached so I futzed for a couple of days casting a new epoxy mount. When I assembled everything I found that the gears unmeshed with this valve, too! Arrrgghhh! I'd tested it with the motor before, but that was manually--just flipping a switch to make it go back and forth. I must have gotten really lucky with that first mount because unless the gears are meshed *exactly*, there's enough slop in the *motor* to unmesh the gears (these are tiny gears with pretty tiny teeth--any slop at all and it's game over). At this point manipulating the valves with ropes is starting to look pretty good :-)

I did manage to figure out a second gear ratio that will give greater mechanical advantage and maybe cause less un-meshing of the gears. The new gears should arrive by the end of the week.

But at least the electronics part works!

In the meantime I have voltage spikes to keep me occupied.....

--Steve

|

|